We have a passion for unconventional solutions that bring your vision to life.

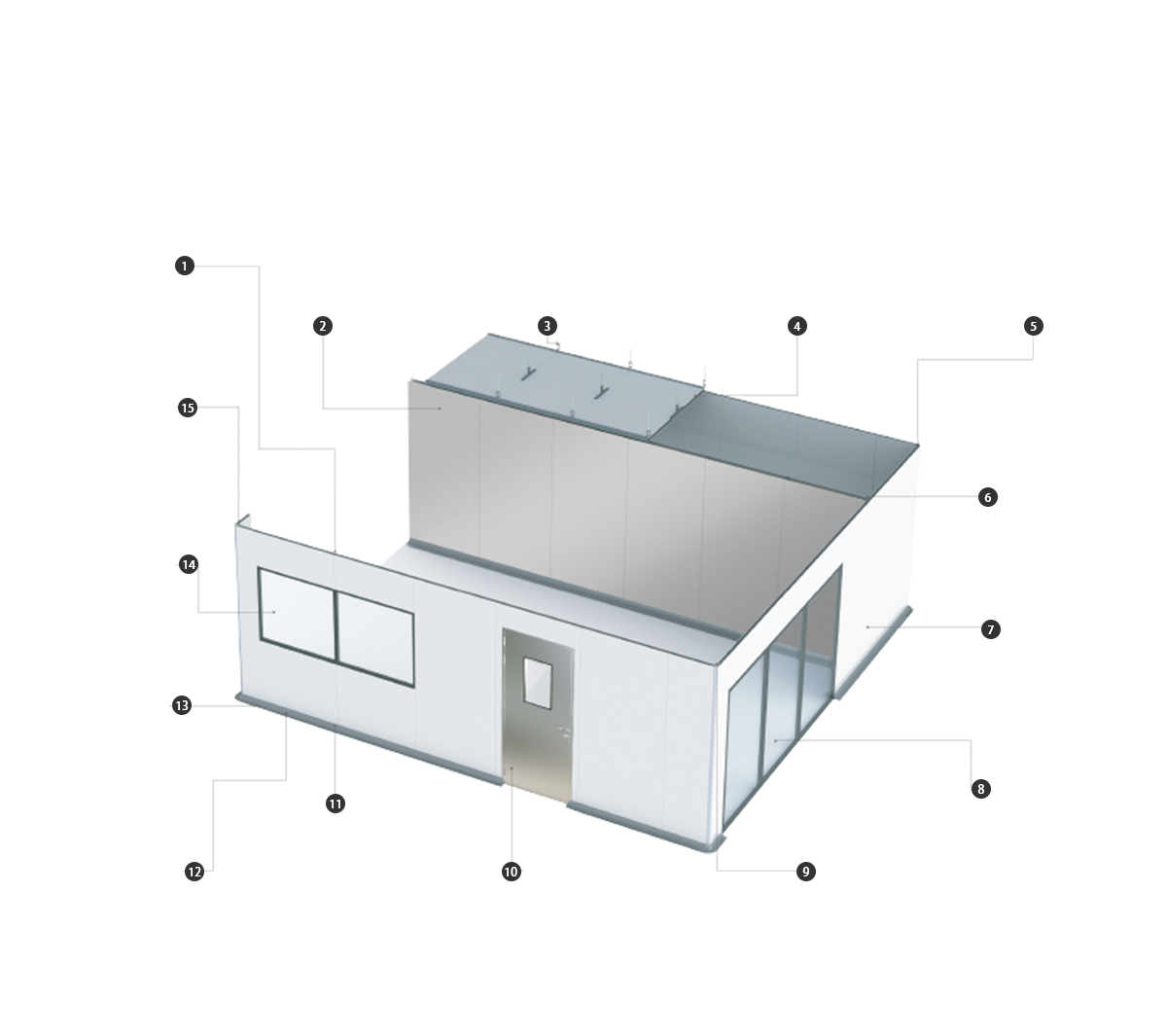

Food Enclosure Structure Solutions

In the "Good Manufacturing Practice for Beverage Enterprises" (GB12695-2003), it is required that the filling area is partially Class 100 (Level 5), the clean area is Class 10000 (Level 7), and the quasi-clean area is Class 100000 (Level 8).

Other design codes include:

Technical Codes for Building Cleanrooms in the Food Industry GB50687-2011, Heating Ventilation and Air Conditioning Design Code GBJ50019-2003, Cleanroom Plant Design Code GB50073-2001, Cleanroom Construction and Acceptance Codes JGJ71-90, Codes for Construction of Acceptance Quality of Ventilation and Air-conditioning Projects GB50243-2002, Specifications for Construction and Acceptance of Refrigeration Equipment Installation Projects GB50210-2001, Specifications for Indoor Environmental Pollution Control in Civil Construction Projects GB50325-2001

Hi! Welcome back.

How are you doing?

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.