We have a passion for unconventional solutions that bring your vision to life.

In recent years, with the continuous intensification of competition in the meat product industry, domestic excellent enterprises have paid more and more attention to the improvement of the production environment, and the requirements for food hygiene and safety in the interior decoration of meat product processing workshops have been increasing.

Shandong Shuochang Food Co., Ltd. (hereinafter referred to as "Shuochang") is a modern large-scale meat food production and processing one-stop enterprise, mainly engaged in breeding poultry, feed processing, poultry raising, slaughtering and processing, food processing and sales and related meat business.

The total investment of Shuochang new factory construction project is 1.2 billion yuan. After completion, the annual output of broiler products and cooked products will be 160,000 tons, of which 20,000 tons will be exported, which will rank first in poultry meat exports in Weifang City. The completion of the project can directly create more than 2,000 jobs in surrounding towns and villages

Shandong Shuochang Food Co., Ltd.

Project address: Weifang, Shandong

Products: stainless steel cleanroom panel, stainless steel waterproof wall base

panel consumption: 24000㎡

Slaughtering and cutting workshop

Usage scenarios: functional room in slaughter workshop - chicken hanging table, blood draining room, hair removal room, pre-cooling room, dividing room, by-product processing room

The challenge faced by the slaughter workshop is that the use of a large amount of water for washing in the production process will generate a large amount of water vapor, resulting in a low temperature and high humidity environment, and the problem of dirt accumulation and bacteria accumulation due to blood stains, water stains and water vapor mixing along the walls.

Therefore, the enclosure system of the slaughterhouse has extremely high requirements for materials such as anti-corrosion, easy cleaning, and high requirements for the tightness of the connection between the wall and the ground.

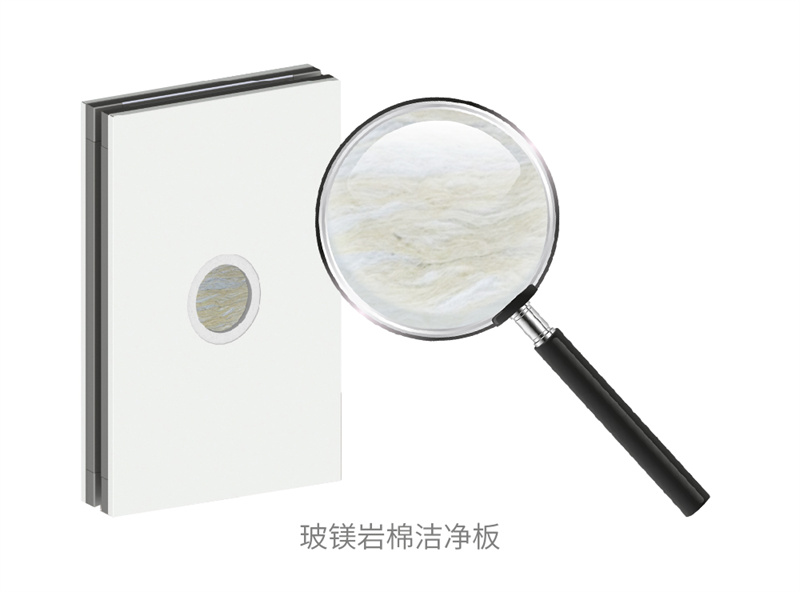

The slaughtering and dividing workshop enclosure product scheme designed by wiskind for the new Shuochang factory is as follows: the wall panels are made of 50mm double-sided stainless steel double-glass magnesia rock wool sandwich panels, and the top panels are made of 75mm thick single-sided stainless steel single-glass magnesia rock wool sandwich panels.

The stainless steel sheet used by wiskind is a stainless steel product with absolute advantages in terms of anti-corrosion, waterproof, anti-fingerprint and other properties after a lot of targeted experiments. We believe that strict control of the panel material is one of the key factors to ensure the superiority of the cleanroom panel.

Cooked Food Processing Workshop

Usage scenarios: functional room of cooked food processing workshop - inner/outer packaging room, thawing room, pre/post-processing room, temporary storage room

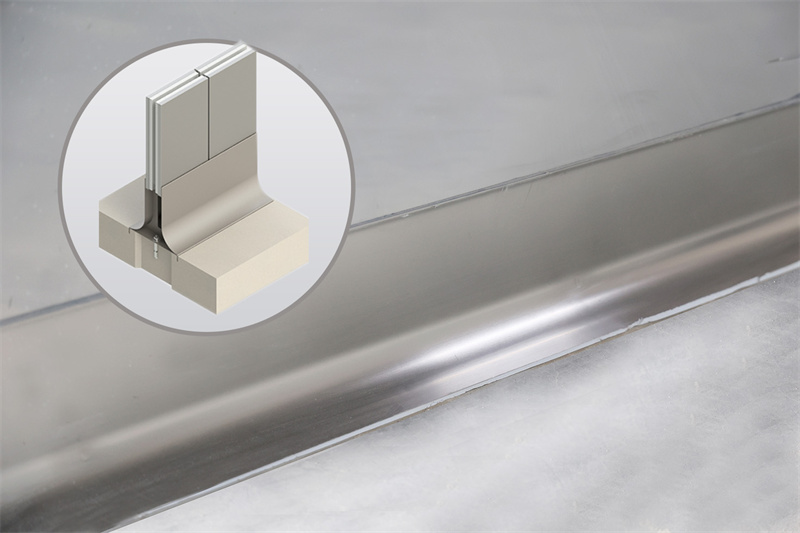

In view of the common high oil, high temperature and high humidity environment requirements in cooked food processing workshops, wiskind designed the cooked food processing workshop enclosure product scheme for the new Shuochang factory: the inner partition wall adopts double-sided stainless steel double-glass magnesium rock wool sandwich panel, and the top panel 75mm single-sided stainless steel single-glass magnesium rock wool sandwich panel is used, and stainless steel waterproof wall base is used to treat the ground and the wall board for sealing.

The stainless steel waterproof wall base can effectively avoid the problem of hygienic dead corners caused by the long-term accumulation of water at the bottom of the board caused by the sliding of water vapor and oil stains on the wall surface.

Wiskind's stainless steel waterproof wall base products are made of high-quality 304 stainless steel, which has been integrally pressed, welded and polished. The product has a long service life, which greatly reduces long-term operation and maintenance costs.

We have always been customer-centric, innovating collaboratively with the industry, and driving market development with technology.

Hi! Welcome back.

How are you doing?

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.