Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.

Wiskind provides a variety of cleanroom sandwich panels that are factory-prefabricated, deliver excellent performance, utilize field splicing, and are designed for streamlined, modular installation. In response to the problems in different industries, we provide solutions such as removable cleanroom panels, VHP resistant cleanroom panels, and cleanroom design software.

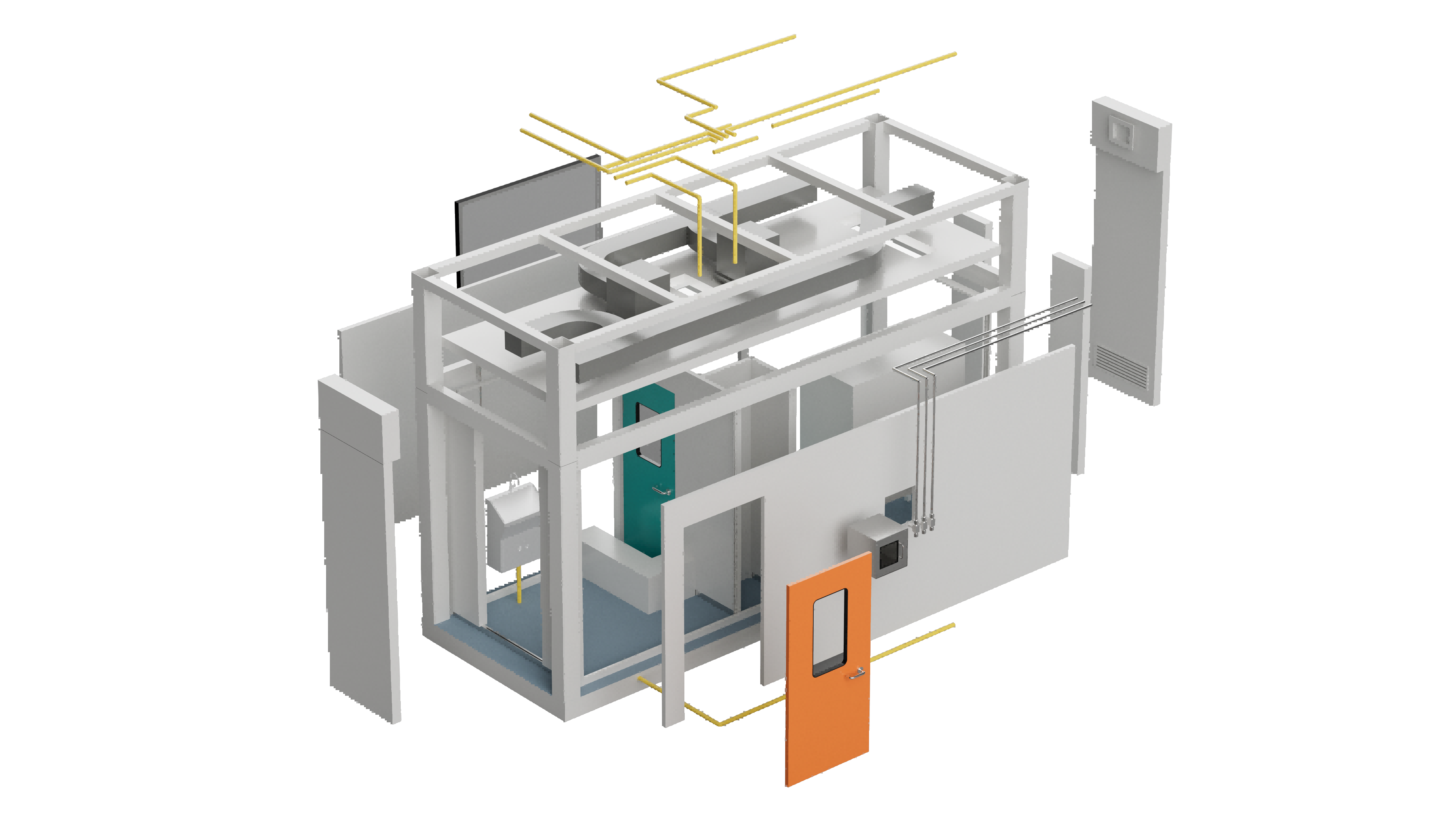

Wiskind cleanroom ceiling system is mainly composed of modular cleanroom panel and ceiling system. It has strong tightness and can be walked. The ceiling system can be perfectly connected with the modular cleanroom panel system products. The ceiling system connection gap is the same as the gap width to ensure The appearance of a clean room. Wiskind cleanroom panel sheet is very resistant to bending and has very strong characteristics.

Wiskind cleanroom doors widely used in cleanroom / sterileroom for workshops, hospitals, pharmaceutical factories, food factories, etc. They has good performance in flatness ,high structural strength, corrosion resistance, no dust, easy to clean. Wiskind cleanroom doors and windows are engineered for your advanced manufacturing industry.

Wiskind cold storage system products Excellent quality, and uniquely charming style,Not only fulfills the functional requirements of fresh-keeping,heat preservation, flatness and deformation resistance of a building,But also boasts outstanding energy saving,environmental protection, and eco-friendliness,while creating unique aesthetics for the building.

Cleanroom is a basic project with a wide range of application industries. In many engineering fields, clean space is needed to meet some high processing requirements.During the construction of clean room, the selection of clean room equipment should be involved. Wiskind provides customers with the types of equipment needed in the clean room and the requirements of clean room construction control.

Wiskind Cleanroom offers customizable, high-quality modular cleanrooms with integrated design, manufacturing, and installation, ensuring efficient and compliant controlled environments for diverse industries.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.

The cleanroom panel supplied in the fields of electronic semiconductors, bio pharmaceutical, food and medicine, aerospace and scientific research, chemical industry and new energy.

Introduced the world's advanced automatic production equipment such as PUMA, RAS and ACL in Italy, and independently developed the world's first automatic Hand-made cleanroom panel production line, which is 6-8 times more efficient than the traditional cleanroom panel production line.

Wiskind cleanroom products show great attention to the optimization and design of the use of main and auxiliary materials, plate structure, and system structure, and have a number of patent technologies.

Wiskind sets up an independent quality assurance center, around the raw material inspection, auxiliary testing, product testing, process audits, laboratory testing five modules start work. Take active test mode, starting strictly controlled from the raw material into the plant. The production process was tracked and controlled.

Wiskind provides comprehensive solution plan for professional cleanrooms and implements all-round, integrated services, including: requirements analysis, project design, quotation, production order, delivery, construction guidance and daily use and maintenance services.

Wiskind has been deeply involved in the industry for over forty years, earning a reputation both domestically and internationally. Our products are widely used in fields such as industrial manufacturing, pharmaceuticals, public buildings, transportation, and commercial facilities. Since 2009, Wiskind has embarked on the business of cleanroom enclosure systems and has been committed to empowering advanced manufacturing with innovative, leading, and reliable cleanroom solutions. Currently, our business covers 72 countries and regions, serving industries such as bio pharmaceuticals, food safety, IC semiconductors, new energy, and display panels.

Over the years, we have focused on creating environmentally friendly multifunctional cleanroom solutions, fulfilling the commitment to aesthetics, reliability, and permanence in the life cycle of cleanroom through continuous innovation. At the same time, by continuously researching and making technological breakthroughs in modular cleanrooms, we have been driving the standardization of construction in the engineering field, achieving efficiency and cost reduction in project engineering.

Wiskind cleanroom is in a leading position in the fields of electronic semiconductor, biopharmaceutical, food and medical, aerospace and scientific research, chemical and new energy industries.

Ready to start a project?

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.