We have a passion for unconventional solutions that bring your vision to life.

Cleanroom Equipment

Cleanroom is a basic project with a wide range of application industries. In many engineering fields, clean space is needed to meet some high processing requirements.During the construction of clean room, the selection of clean room equipment should be involved. Wiskind provides customers with the types of equipment needed in the clean room and the requirements of clean room construction control.

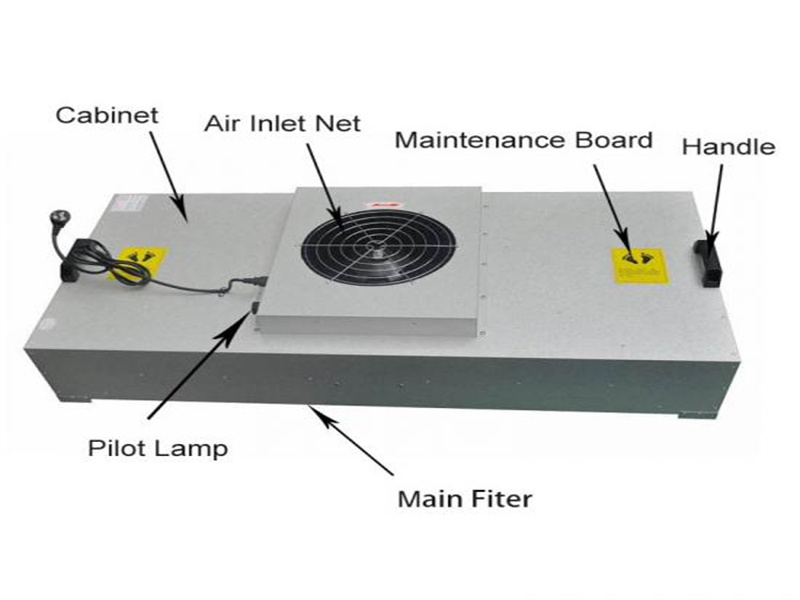

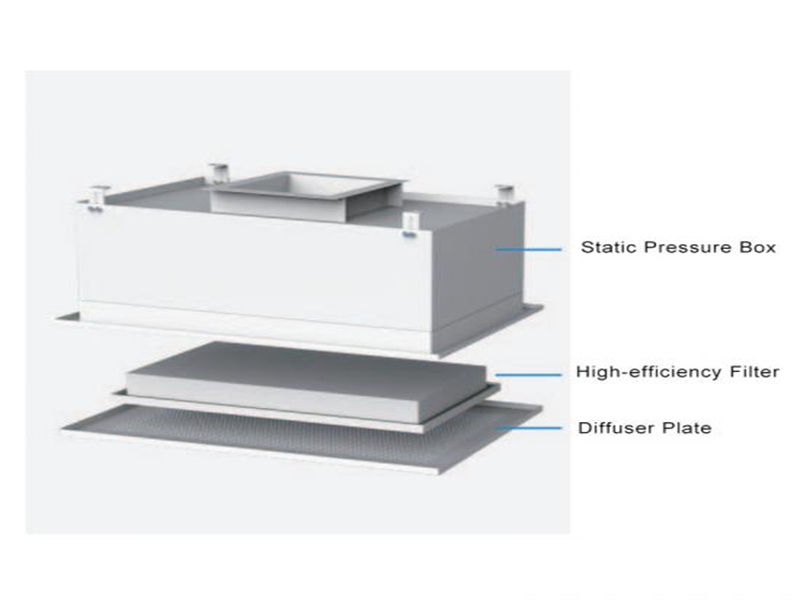

Cleanrooms rely on a range of specialized cleanroom equipment to create a controlled environment that minimizes particulate contamination. High-performance air filtration systems, such as HEPA and ULPA filters, are vital for removing airborne particulates. Laminar flow hoods deliver a consistent stream of filtered air to safeguard sensitive processes, while air showers effectively remove contaminants from personnel or materials entering the cleanroom. Additionally, pass-throughs enable secure material transfers between rooms, and fume hoods safely handle hazardous vapors. Monitoring and testing tools, such as particle counters and sensors for temperature and humidity, are critical components of equipment for clean room operations to ensure compliance with strict industry standards.

Selecting the right clean room products and equipment requires careful evaluation to meet your facility's specific needs. Start by researching the types of cleanroom equipment available to determine which solutions align best with your cleanroom's operational requirements. Prioritize high-quality systems designed to meet the rigorous demands of a controlled environment. Opting for equipment certified by an independent organization is essential to ensure adherence to industry regulations. Budget considerations are also key, as equipment for clean room use comes in a variety of price ranges, allowing you to balance cost with performance while maintaining compliance and efficiency.

To keep cleanroom equipment efficient and durable, consistent maintenance and care are crucial. Regularly cleaning and sanitizing the clean room products helps prevent contamination and ensures optimal performance. Routine inspections to verify that all components are functioning correctly, along with timely replacement of worn or damaged parts, are necessary to maintain operational integrity. Following the manufacturer's guidelines for the upkeep of equipment for clean room environments is vital to preserving performance and ensuring ongoing compliance with cleanroom standards.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.