We have a passion for unconventional solutions that bring your vision to life.

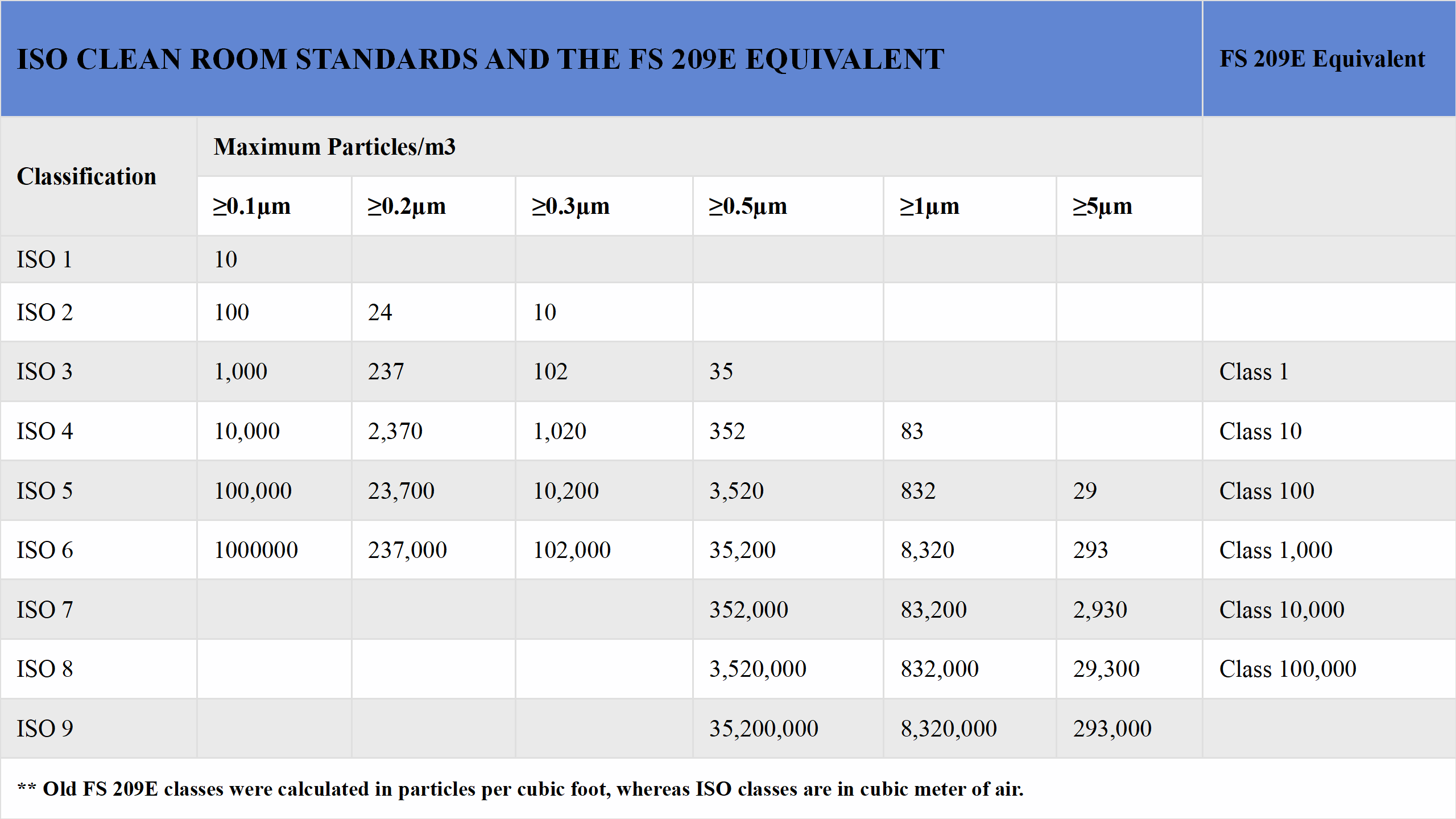

An ISO-6 cleanroom represents one of the higher tiers of cleanliness in the cleanroom classification system established by the International Organization for Standardization, a private entity with 167 national standards bodies as members. This classification is widely adopted in the United States, particularly for pharmaceutical, medical device, biotech, and life-science cleanrooms. Globally, outside of the semiconductor industry, the ISO cleanroom standards are applied across various sectors. In contrast, the United States has historically used the FED 209E classification system for industrial applications like semiconductor and printed circuit board manufacturing. The ISO system measures particle concentration in particles per cubic meter, while the FED 209E system uses particles per cubic foot. An ISO-6 cleanroom aligns with the FED 209E Class 1000 cleanroom, indicating comparable cleanliness levels.

An ISO-6 cleanroom maintains stringent environmental controls, requiring 180 air changes per hour using HEPA-filtered air and allowing fewer than 293 particles per cubic meter that are 5 microns or larger. For context, a typical air-conditioned office space would have over 100 times more particles of this size. The ISO-6 classification also sets limits for particles larger than 0.5 microns and 1 micron, ensuring a highly controlled environment. Airflow in these cleanrooms is typically recirculating, where air is exhausted through low return air grills to a plenum, cleaned by HEPA or ULPA fan filter units, and reintroduced into the cleanroom. This continuous filtration process, occurring 180 times per hour, creates an exceptionally clean environment. ULPA filters, which capture particles as small as 0.12 microns, are often preferred over HEPA filters, which filter down to 0.3 microns, to achieve the stringent cleanliness required for ISO-6 standards.

ISO-6 cleanrooms are essential in industries requiring precise contamination control. These include semiconductor manufacturing, where microchip production demands minimal particle interference, and optics manufacturing, which requires a dust-free environment to ensure product clarity and precision. Ceramics manufacturing also utilizes ISO-6 cleanrooms to maintain material purity, while laser testing facilities rely on them for accurate and uncontaminated results. As for pharmaceutical cleanroom design, pharmaceutical manufacturing benefits from ISO-6 cleanrooms to ensure sterile production environments, and research and development facilities use them to conduct sensitive experiments without contamination risks. These applications highlight the versatility and critical role of ISO-6 cleanrooms in advanced manufacturing and scientific research.

Gown rooms or airlocks are vital for preserving the integrity of an ISO-6 cleanroom. With a limit of only seven particles per cubic foot larger than 5 microns, even a brief opening of a door to an unclean exterior could introduce thousands of particles, compromising the cleanroom's standards. Gown rooms equipped with HEPA FFU act as a buffer, reducing particle exposure when personnel enter or exit. This setup ensures that the cleanroom remains a controlled environment, protecting the sensitive processes conducted within.

Maintaining an ISO-6 cleanroom's cleanliness requires strict gowning protocols. Personnel typically wear knee-high cleanroom shoe covers to prevent tracking dirt into the space and full-body bunny suits made from non-particulating, cleanroom-approved materials. These garments are available as disposable or washable options, with washable garments sent to specialized cleanroom laundries. Proper gowning is crucial to prevent particle contamination and uphold the ISO-6 classification's stringent standards.

What Is an ISO 8 Cleanroom Classification?

What Is an ISO 7 Cleanroom Classification?

What Is an ISO 5 Cleanroom Classification?

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.