We have a passion for unconventional solutions that bring your vision to life.

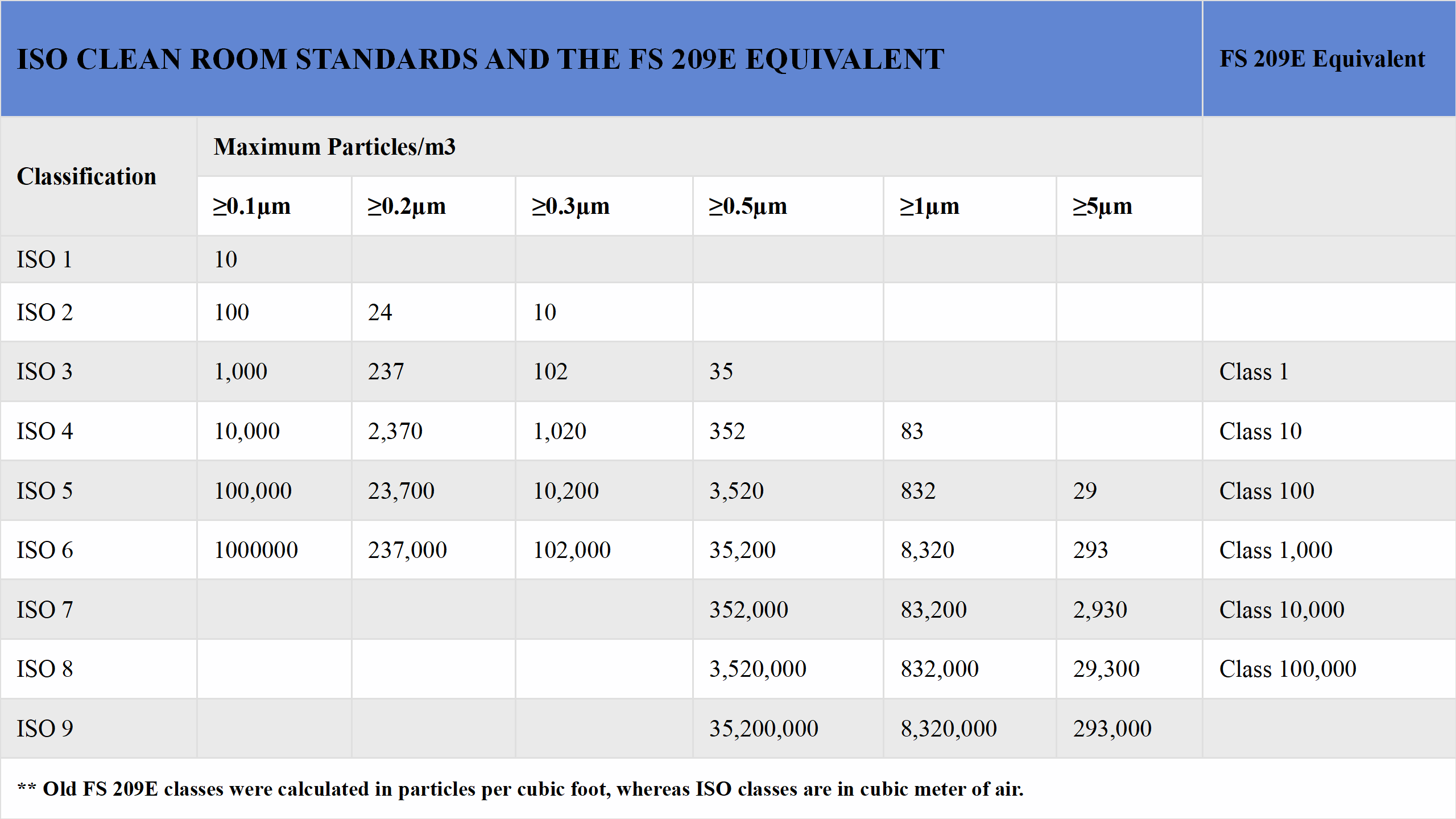

Cleanrooms are specialized environments designed to maintain strict control over airborne particles, and their classification is determined by the number and size of particles allowed per cubic meter of air.

The ISO-7 classification, as defined by the ISO 14644-1 Cleanroom Standards, permits a maximum of 352,000 particles of 0.5 microns or larger per cubic meter and requires at least 60 air changes per hour. This level of cleanliness makes ISO-7 cleanrooms suitable for a variety of industries, including pharmacy compounding compliant with USP797/800 standards, semiconductor processes like bonding, metal deposition, and testing, as well as pharmaceutical manufacturing in non-critical areas. Other applications include aerospace manufacturing, printed circuit board production, medical device manufacturing, nutraceutical production, and precision manufacturing. These cleanrooms are often constructed using modular or hardwall systems, which provide robust air quality control and operational efficiency tailored to specific industry requirements.

Hardwall ISO-7 cleanrooms are durable, permanent structures designed for superior contamination control, ideal for long-term, high-performance environments. Built with non-porous materials like epoxy-coated gypsum board or stainless steel, they resist particle buildup and support thorough cleaning. These cleanrooms integrate advanced HVAC systems for precise temperature and humidity control, maintaining positive pressure to block external contaminants. They suit pharmaceutical manufacturing, semiconductor fabrication, and medical device production. Custom features like airlocks, pass-throughs, and sealed lighting ensure ISO-7 compliance and functionality. Designed for longevity, hardwall cleanrooms withstand rigorous cleaning and allow future modifications, providing a stable, controlled environment for sensitive processes and high-quality production outcomes.

Modular ISO-7 cleanrooms offer a versatile, efficient solution with rapid installation and adaptability. Constructed from prefabricated clean room panel of lightweight materials like aluminum or powder-coated steel, they ensure ISO-7 compliance. Their modular design allows quick setup, reconfiguration, and upgrades to higher classifications like ISO-6. Equipped with HEPA filtration and customizable HVAC, they maintain consistent air quality. Ideal for aerospace, printed circuit board production, and research, these cleanrooms support changing operational needs. Features like gowning areas and sealed lighting enhance functionality, while scalability ensures cost-efficiency. Modular ISO-7 cleanrooms balance performance and flexibility, meeting demands for dynamic, controlled environments.

Softwall ISO-7 cleanrooms offer a more flexible and cost-effective alternative, utilizing clear vinyl curtains or strip curtains for entrances, supported by a painted steel or anodized aluminum frame. These cleanrooms feature ceiling-mounted HEPA fan filter units and lighting, and smaller setups may include casters for mobility. However, softwall cleanrooms have limitations, such as the lack of temperature control, inability to maintain measurable positive pressure, and walls that cannot be cleaned as thoroughly as hard-wall designs. These cleanrooms are often used within existing ISO-8 hard-wall cleanrooms, warehouses, or for tasks like product weighing during packaging, inspection stations, or temporary cleanroom setups.

ISO-7 cleanrooms are equipped with specialized components to maintain their stringent cleanliness standards. These environments typically include gowning rooms or airlocks to prevent contamination from entering, along with product pass-throughs to safely transfer materials. The flooring is often heat-welded vinyl or epoxy, which is easy to clean and resistant to particle accumulation. Air conditioning systems regulate temperature, while HEPA fan filter units ensure clean air circulation. Sealed lighting prevents dust ingress, and magnehelic gauges monitor room air pressure. Personnel wear non-particulating bunny suits, booties, and hoods to minimize contamination, and some facilities incorporate air showers and sticky mats at entrances and exits. Stainless steel benches, gown racks, and hands-free sinks are also common to maintain hygiene and functionality within the cleanroom.

ISO-7 cleanrooms are versatile and widely used across multiple industries due to their balanced cleanliness requirements. They are commonly employed in USP797/800 compounding pharmacies, medical device manufacturing, and printed circuit board production. Other applications include pharmaceutical solution preparation, cream and ointment manufacturing, liquid production, CBD extraction, laser cleanrooms, precision manufacturing, aerospace composite repair, semiconductor testing and packaging, and research and development. These cleanrooms can be configured as modular, stick-built, or softwall designs, with modular cleanrooms offering advantages like quick installation, easy modification, and the potential to upgrade to a higher classification, such as ISO-6. Stick-built cleanrooms, constructed with gypsum board and epoxy-painted walls, are slightly less expensive but take longer to build and are harder to modify. Softwall cleanrooms, while cost-effective, are limited to one-pass air systems and cannot incorporate air conditioning.

To maintain the stringent standards of ISO-7 cleanrooms, effective filtration and contamination control are paramount. These cleanrooms employ HEPA filters within a negative pressure plenum, utilizing ceiling-mounted fan filter units and low wall air returns to create laminar airflow that sweeps contaminants downward and out, ensuring compliance with particle limits and high air quality for sensitive processes. Personnel must wear specialized non-particulating garments, including shoe covers, head coverings like bouffants or hoods, and knee-length jackets, which may be disposable or washable, to prevent particle introduction and preserve the cleanroom’s integrity. Gowning rooms or airlocks, equipped with HEPA filtration, are critical, as the 60 air changes per hour in ISO-7 cleanrooms mean that a brief door opening to a non-clean environment can disrupt air quality, requiring 10 to 15 minutes to recover. With airlocks, this recovery time is reduced to under 5 minutes, ensuring consistent cleanliness and operational efficiency.

What Is an ISO 8 Cleanroom Classification?

What Is an ISO 6 Cleanroom Classification?

What Is an ISO 5 Cleanroom Classification?

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.