We have a passion for unconventional solutions that bring your vision to life.

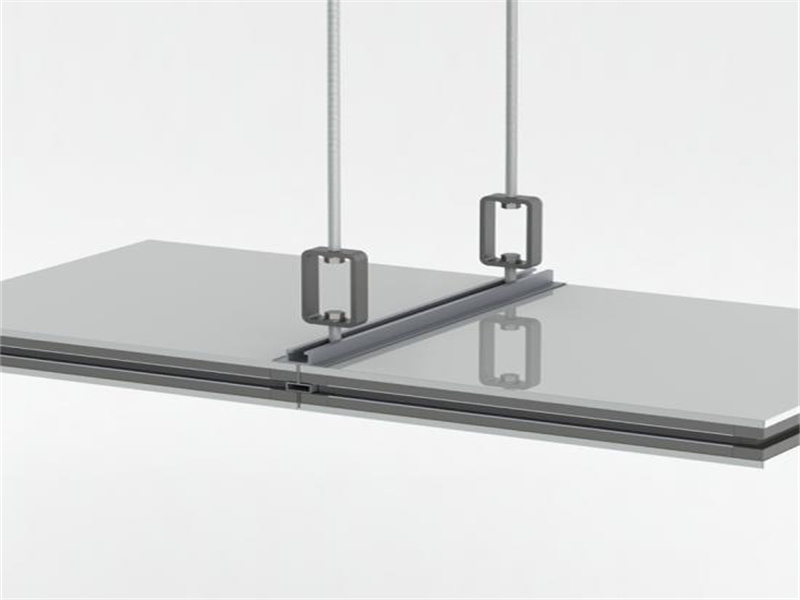

Cleanroom Ceiling System

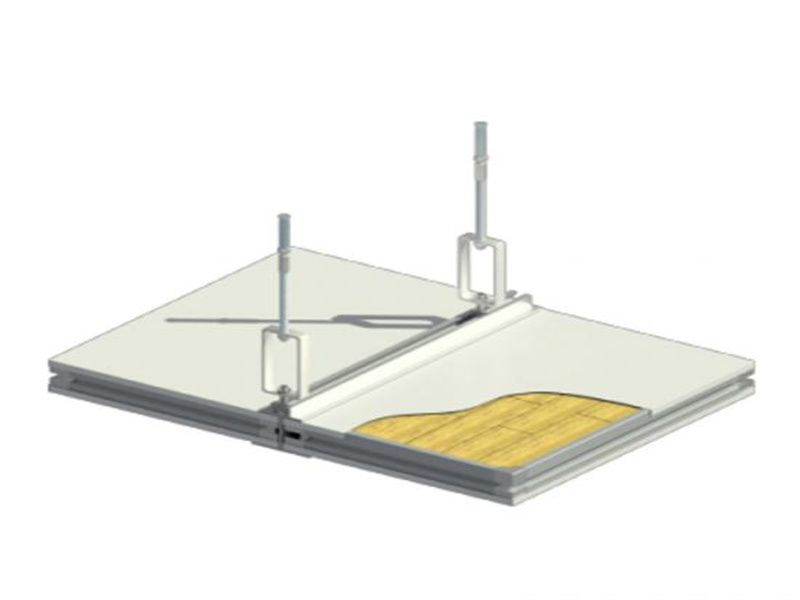

Wiskind cleanroom ceiling system is mainly composed of modular cleanroom panel and ceiling system. It has strong tightness and can be walked. The ceiling system can be perfectly connected with the modular cleanroom panel system products. The ceiling system connection gap is the same as the gap width to ensure The appearance of a clean room. Wiskind cleanroom panel sheet is very resistant to bending and has very strong characteristics.

When selecting a cleanroom ceiling system, options such as stick-built or modular clean room ceiling panels are available. It’s crucial to evaluate factors like ease of maintenance, installation flexibility, and the system’s adaptability to meet the specific needs of your cleanroom ceilings. A well-chosen system ensures long-term performance and compliance with industry standards.

The choice between onsite assembly and offsite manufacturing for clean room ceilings depends on whether the cleanroom is being constructed in a new space or retrofitted into an existing one. Concurrent construction activities may limit available space or time, making offsite manufacturing a more efficient option for installing cleanroom ceiling systems.

When designing a clean room ceiling grid, consider three critical structural aspects: the support for structures above the cleanroom, the weight of components hanging below, such as an automated material handling system (AMHS), and whether the grid needs to be walkable. Accessibility is vital for maintenance, inspections, and housing air handlers or fall protection systems. A robust cleanroom ceiling ensures easy access to the ceiling plenum, minimizing downtime. For industries like semiconductors, the grid must support AMHS load requirements, making it essential to partner with a provider experienced in ceiling clean room designs.

Cleanroom ceilings must seamlessly integrate lighting, HEPA filters, sprinklers, and other utilities while maintaining stringent cleanliness standards. Understanding how these components are incorporated into the clean room ceiling panels is critical to avoid compromising functionality or risking contamination. Proper placement of lighting and wiring within the clean room ceiling grid enhances overall performance and efficiency.

Materials used in cleanroom ceiling systems vary in durability, chemical resistance, and cleanability. It’s important to explore the materials for clean room ceiling panels, the grid structure, and additional components to ensure they meet the specific demands of your manufacturing processes, such as those in pharmaceuticals or electronics.

As production demands evolve, cleanroom ceilings may need to accommodate future expansions. Selecting a cleanroom ceiling that can adapt without requiring extensive modifications ensures long-term flexibility and cost-effectiveness, supporting the scalability of your operations.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.