We have a passion for unconventional solutions that bring your vision to life.

In June 2020, the new version of the veterinary drug GMP management specification will be implemented, and a more explicit acceptance specification for veterinary drug production management and quality control will be proposed. In addition, with the outbreak of animal epidemics and the increasing pressure on prevention and control, the number of animal vaccine batches issued in China has shown an overall growth trend, which also poses new challenges to biotechnology companies engaged in animal vaccines and diagnostic reagents.

Zhejiang Ceva Ebvac Biotech Co., Ltd. Specializing in the research and development, production, sales and technical services of animal vaccines and diagnostic reagents. It is committed to the research and development of high-end products such as subunit vaccines, virus vector vaccines, nanoparticle vaccines, diagnostic reagents, etc.

Zhejiang Ceva Ebvac Biotech invest nearly 100 million yuan to build a biological product, genetic engineering vaccine and biological drug research and development base meeting international standards, covering an area of 16340 square meters, including inactivated vaccine workshop, attenuated live vaccine workshop, supporting laboratory animal room, quality inspection room and research and development center.

Zhejiang Ceva Ebvac Biotech Co., Ltd.

Project address: Hangzhou, Zhejiang

Products: four sides frame cleanroom panel, clean steel door, clean window, integrated corner panel

Panel area: 18962 ㎡

——Project Scheme Analysis——

Wiskind strictly follows the new version of veterinary drug GMP standard, provides Ceva Ebvac Biotech with a solution for the clean enclosure structure system of the production workshop, and helps it establish a scientific and strict sterile drug production environment, process, operation and management system. The internal surface of the drug production clean area should be flat and smooth, without joints, tight interfaces, no particles falling off, to avoid dust accumulation and facilitate effective cleaning, and should be disinfected when necessary. This has a more stringent standard for the interior decoration materials used in the clean room walls, floors and ceilings.

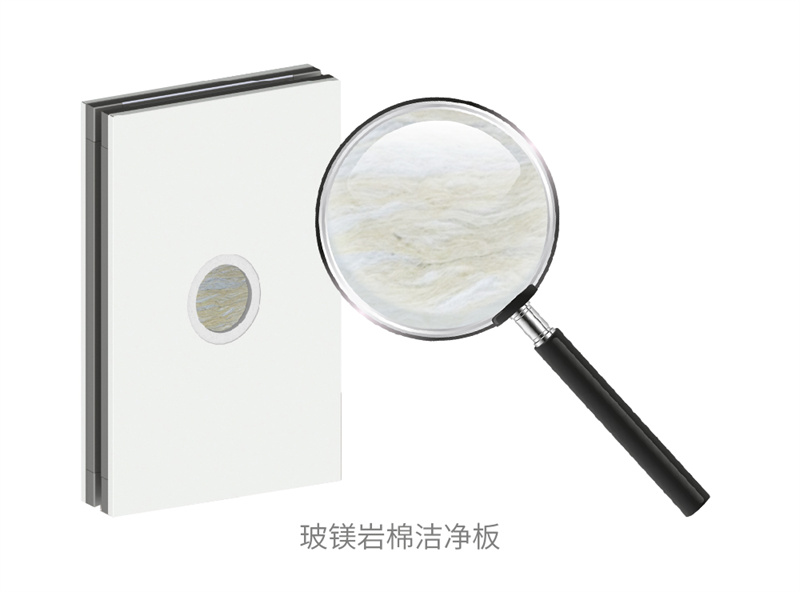

①Wall panel

The cleanroom panel series adopts Wiskind glass magnesium rock wool cleanroom panel. The glass magnesium and high-quality hydrophobic rock wool board form a seamless structure with higher flatness. It is a multi-functional sandwich composite panel that meets the personalized requirements and integrates fire prevention, heat preservation, corrosion resistance and pollution resistance.

All walls involving switches, sockets and air inlets/outlets shall be prefabricated with holes and column cladding panels to avoid core material dust pollution caused by on-site cutting and opening.

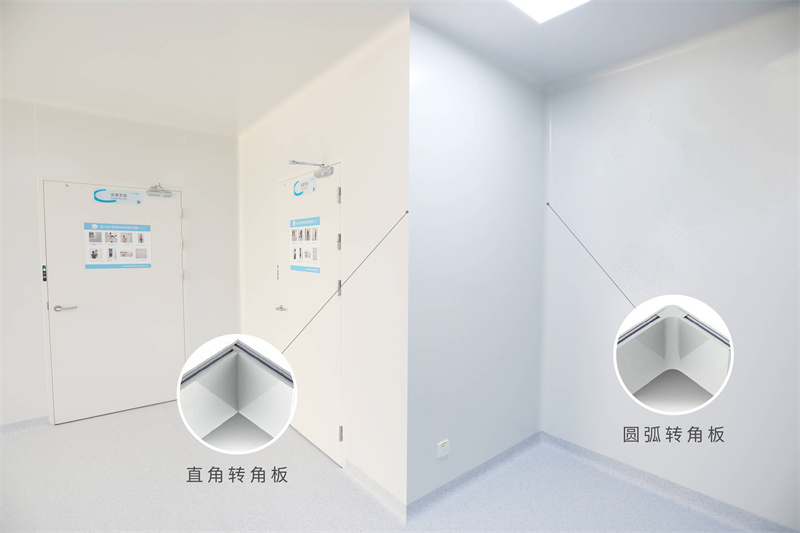

②Corner/Connection

In order to avoid the thermal bridge effect of the enclosure structure caused by the traditional corner method, Wiskind attaches great importance to the design scheme of the structural thermal bridge part of this project - the corner.

In the design process, we adopted an integrated corner panel to make the position of the corner panel smooth and seamless, and eliminate the phenomenon of air leakage and joint dust accumulation. The special thermal insulation treatment can effectively avoid the common thermal bridge effect of traditional corners. Not only that, it greatly reduces the difficulty of daily cleaning, and reduces the chance of wall blistering caused by frequent disinfection.

Comparison of installation effects

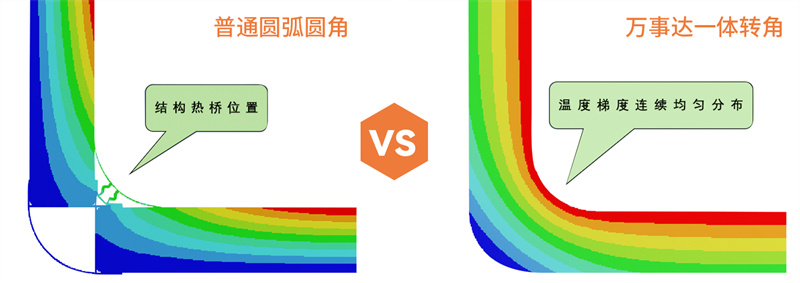

Comparison of thermal analysis diagram

As shown in the thermal analysis diagram, the red area is the area with relatively high temperature, and the blue area is the area with relatively low temperature. The temperature gradient of traditional corner design is large, and thermal bridge effect is easy to occur. The temperature gradient of Wiskind patented all-in-one corner panel is continuously and evenly distributed, and the thermal bridge phenomenon is basically solved.

Wiskind Integrated Corner Panel Patent Certificate

③Doors and Windows

In the selection of doors and windows for this project, Wiskind selected cleanroom steel doors for customers. Wiskind cleanroom steel door is made of high-quality galvanized steel panel with high strength and corrosion resistance. The surface is sprayed with imported powder, with stronger adhesion and more beautiful color.

Wiskind cleanroom steel door adopts the integral door leaf panel folding and covering forming process, and the integral door frame and corner assembly welding adopt aerospace and automobile welding standards, with smooth shape and stable structure. No deformation after 500000 opening and closing, and super standard load fatigue test.

We are committed to becoming a trustworthy enterprise in the field of clean room enclosure system, focusing on technological innovation and improving product service capabilities, and creating a safe, lasting, beautiful and friendly production environment for the biomedical industry. Wiskind, making the clean space permanent and beautiful!

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.