We have a passion for unconventional solutions that bring your vision to life.

Industrial cleanroomroom workshops have been developed in China for more than 40 years and have already become relatively mature in meeting the needs of cleanroom production. A number of professional industrial cleanroomroom plant production, construction and service companies have also grown up in the pharmaceutical, electronics, food and other industries. Especially since this year, some leading companies in the cleanroomroom industry have been listed on the market, which makes us feel that the cleanroomroom industry has entered a period of rapid development.

With the development of new technologies, changes in the international situation, and relevant policy requirements in recent years, more and more industries have created demands for cleanroomroom factories. These demands are no longer just to meet regulatory standards and production environments. Let’s briefly talk about the development trends of industrial cleanroom factory construction based on some changes we have encountered in the industry.

Trend 1: Fast construction and iteration

The first time I felt the owner’s requirement for fast construction was during the construction of the COVID-19 vaccine factory after the epidemic. Especially when inactivated vaccine equipment involves biosafety, its demonstration, design, and acceptance are much faster than before, not to mention the construction of cleanroom production areas. In recent years, due to the rapid iteration of technology in downstream industries, such as the cleanroom production of power batteries, not only requires fast construction, but also a fast iteration speed. According to the previous construction speed, it may not be able to keep up with the rapid development needs of the new energy industry. Some sub-industries, such as biomedicine and integrated circuits, also show this trend.

Trend 2: Pay more attention to energy saving

The impact of the "double carbon" policy on the industrial sector has slowly begun to be reflected in policies in the past two years. Industrial cleanroom workshops, especially those in the electronics industry, consume much more energy than general industry and commerce. Our current implementation of "double carbon" is still focused on saving electricity. The majority of electricity consumption in cleanroomroom factories comes from HVAC. In the past, because the equipment operation itself consumed a lot of electricity and had to meet standards and yield rates, we often made "high configurations" in HVAC during the design stage, and then added more layers during the subsequent construction and operation processes, resulting in electricity usage is high. However, in the past two years, in order to achieve power saving in the subsequent operation stage, even areas with biosafety safety requirements have explored the rational use of return air. In addition, in terms of design, reducing the area of the cleanroom area is also an important exploration in the direction of energy conservation. It can be made small but not large, and a cleanroom shed can be used instead of a cleanroom. Even in the data center industry, integrated cabinets can be directly used to achieve cleanliness and refrigeration.

Trend 3: Requirements for the beauty of space

In the current market, it is obvious that everyone has higher requirements for the beauty of clean rooms. In the past, industrial plants were designed and constructed with the sole goal of meeting production and improving efficiency. Only the few owners with "pursuit" would spend more money on making cleanroom plants beautiful. With the development of the industry, there are two big demands that make everyone put forward requirements for aesthetics. First, it needs to meet the industry's inspection requirements for investors and governments; second, the industry also needs to display products to customers in order to sell products. This puts forward higher requirements for materials, design and construction. For example, Baosteel and Wiskind jointly developed a wall panel with a special color for clean rooms.

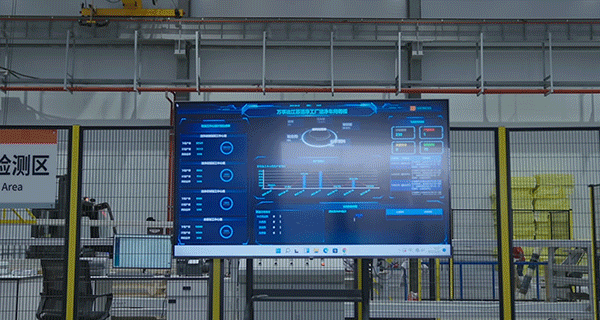

Trend 4: Digital Transformation

Not only industrial cleanroom plants, almost all manufacturing industries are currently exploring digital transformation. In industries such as pharmaceuticals and integrated circuits, the confidentiality of their own processes is relatively strict, and they will be relatively closed during the process of digital transformation. In industrial cleanroom workshops, the main direction of change is relatively clear, which is to use Internet of Things technology to realize digital twin directions such as data collection, organization, visualization, simulation, etc. At present, the manufacturing industry with clean demand is generally slow in the process of digital transformation, but it is a relatively clear direction.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.