We have a passion for unconventional solutions that bring your vision to life.

In industries with stringent environmental control requirements, cleanrooms are crucial for ensuring product quality and production efficiency. With technological advancements, modular cleanrooms are increasingly becoming the preferred choice for many businesses. So, why choose a modular cleanroom? What types of businesses are they suitable for? And what are the differences and advantages compared to traditional cleanrooms?

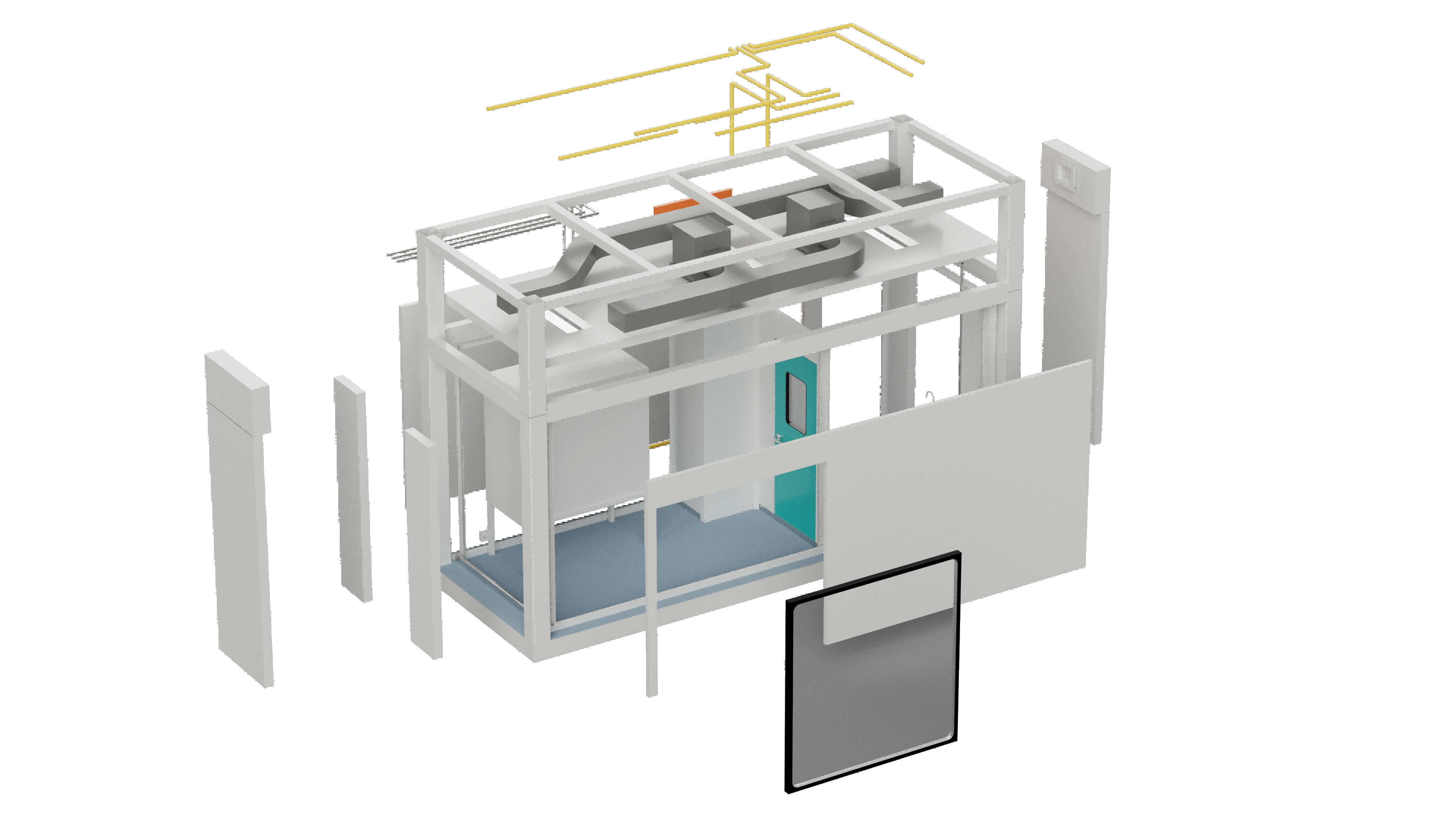

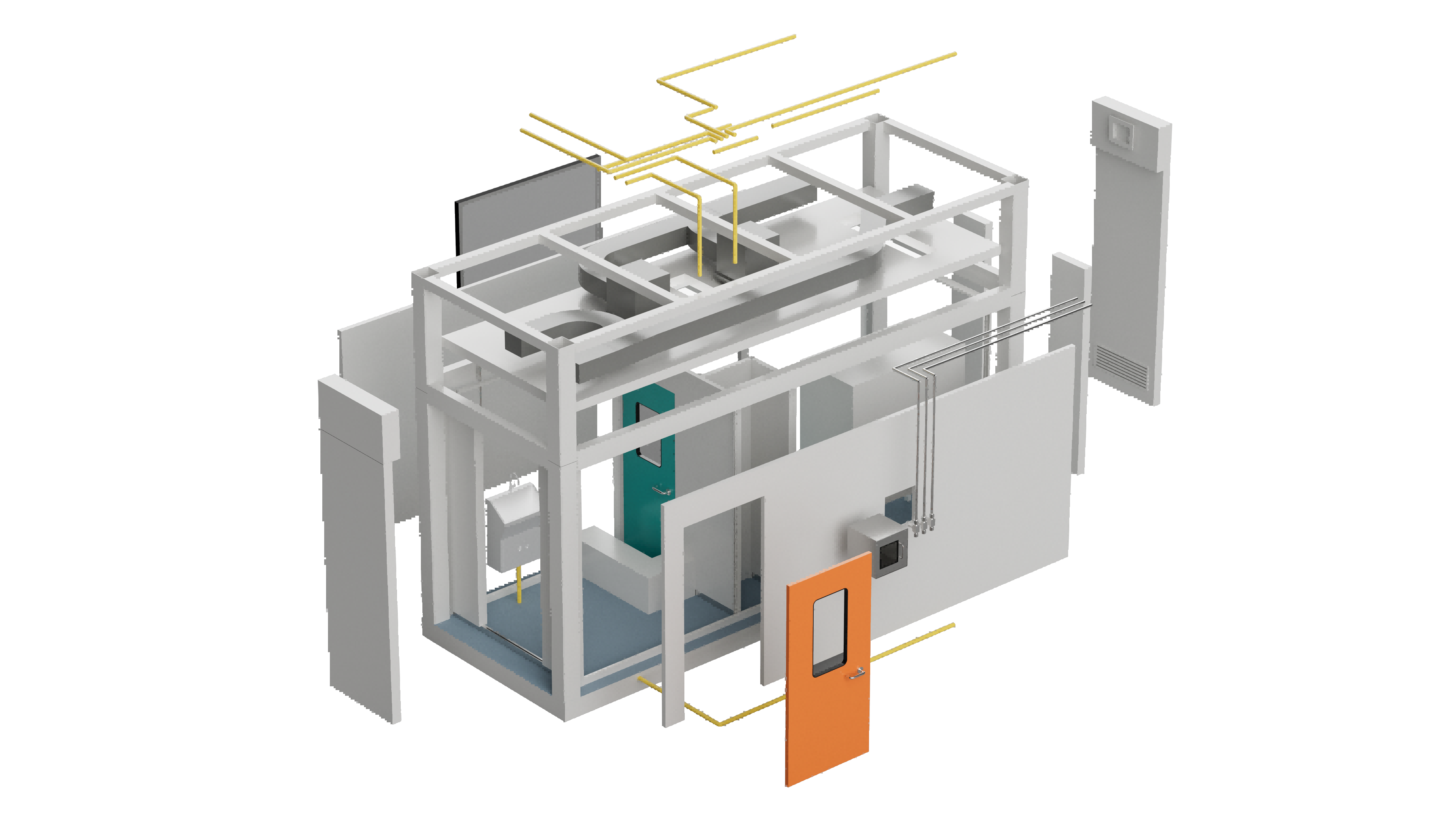

The core reasons for choosing a modular cleanroom lie in its flexibility, controllability, and cost-effectiveness. In today's rapidly changing business environment, companies need production spaces that can quickly respond to market demands and technological upgrades. Modular cleanrooms provide this flexibility because, like LEGO bricks, they can be rapidly assembled, disassembled, or expanded as needed. This characteristic significantly shortens construction cycles, reducing upfront investment and future modification risks.

Modular cleanrooms are suitable for a wide range of industries and business types, especially those that:

Have strict requirements for construction periods, such as emerging biomedical, electronics manufacturing, or semiconductor companies that need to start production quickly.

May need to adjust or expand future production lines, like R&D companies, CROs (Contract Research Organizations), or CMOs (Contract Manufacturing Organizations), which might frequently need to change cleanroom layouts or classifications.

Lease factory spaces or have concerns about fixed asset investment. The mobility and reusability of modular cleanrooms make them a more attractive option.

Need to comply with strict industry standards but have limited budgets or time. Modular systems often come pre-certified to relevant standards, reducing the complexity of on-site validation.

Are sensitive to disruption during construction. Modular cleanrooms involve minimal on-site construction, keeping interference with existing operations to a minimum.

To understand the value of modular cleanrooms, we need to compare them with traditional "brick-and-mortar" cleanrooms.

Modular Cleanrooms: Prefabricated components are manufactured in a factory, requiring only rapid on-site assembly. The construction period is typically 50% or more shorter than traditional cleanrooms.

Traditional Cleanrooms: All work, from civil engineering to decoration and equipment installation, is completed on-site. This process is lengthy and susceptible to external factors like weather.

Modular Cleanrooms: The structure is flexible, easy to disassemble, relocate, modify, or expand. When production needs change, the cleanroom layout can be easily adjusted, or the scale expanded, and it can even be entirely relocated for reuse.

Traditional Cleanrooms: Once built, the structure is fixed. Modifications or expansions are costly and time-consuming, and relocation is almost impossible.

Modular Cleanrooms: Key components are prefabricated in a controlled factory environment, allowing for stricter and more consistent quality control, which reduces uncertainties associated with on-site construction.

Traditional Cleanrooms: Quality heavily relies on the skill and management of the on-site construction team, making them prone to quality fluctuations.

Modular Cleanrooms: While the initial per-square-meter cost might be slightly higher, their total lifecycle cost is often lower due to shorter construction periods, lower on-site labor costs, flexible future modifications, and reusability. Furthermore, rapid commissioning means earlier revenue generation.

Traditional Cleanrooms: Upfront civil engineering and decoration costs are high, and additional costs for modifications or expansions are also significant.

Modular Cleanrooms: On-site construction is minimal, producing very little noise, dust, and waste, thus minimizing interference with existing production environments.

Traditional Cleanrooms: On-site construction significantly impacts the surrounding environment, potentially requiring prolonged shutdowns or relocation of production.

Modular cleanrooms offer a highly attractive solution for modern enterprises due to their rapid deployment, high flexibility, excellent quality control, and superior total lifecycle cost. For businesses that prioritize efficiency, focus on future development, and aim to respond quickly to market changes, choosing a modular cleanroom is undoubtedly a crucial step toward success. If you are looking for a reliable modular cleanroom manufacturer, contact us for a quote, and we are committed to providing integrated modular cleanroom solutions!

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.