We have a passion for unconventional solutions that bring your vision to life.

At Wiskind Cleanroom, we specialize in providing advanced cGMP modular cleanroom solutions, capable of quickly and efficiently building a contamination-free workspace that meets the most stringent standards. Our modular design philosophy means you get a highly customizable, expandable, and cost-effective cleanroom to meet your evolving needs.

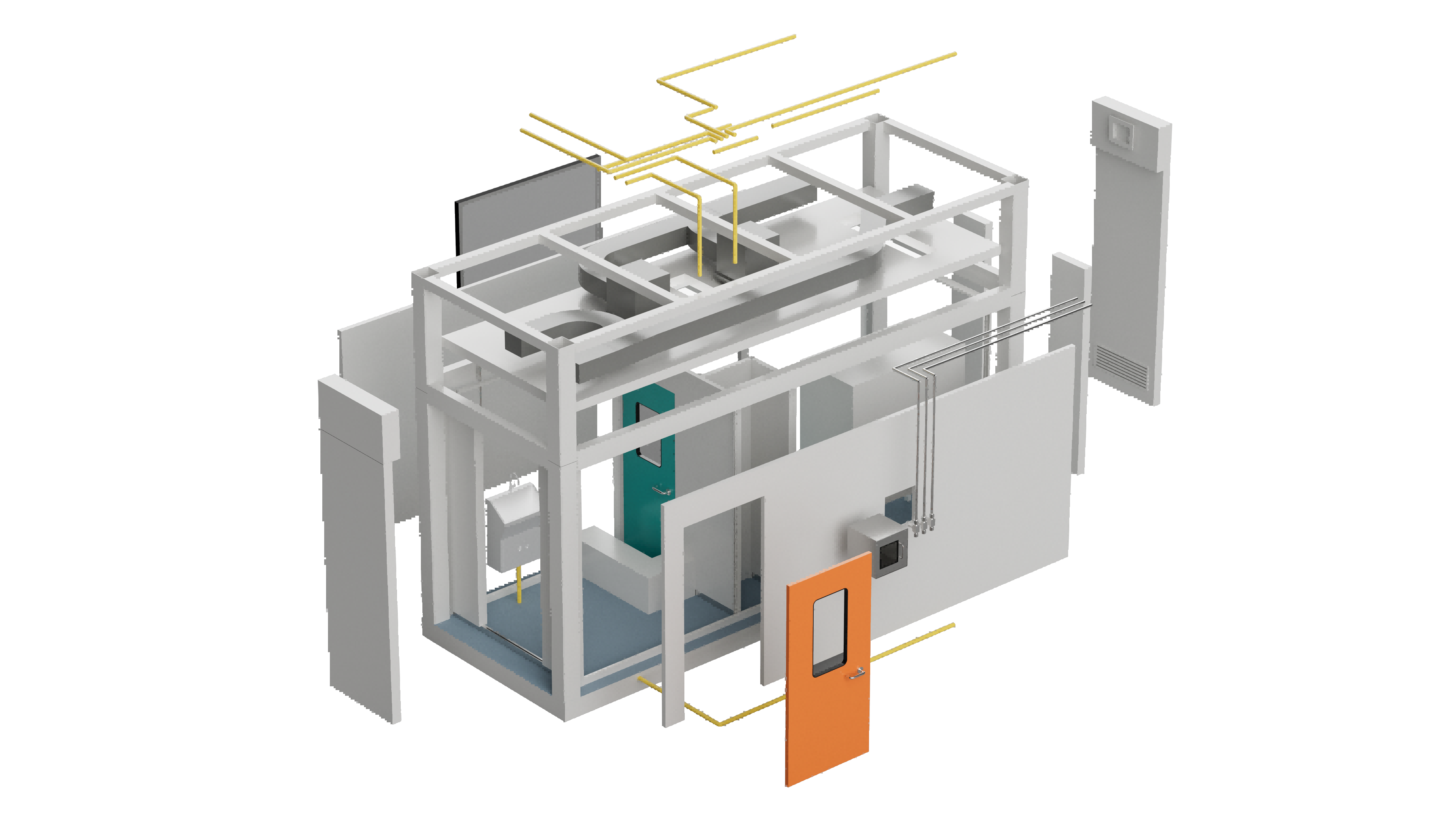

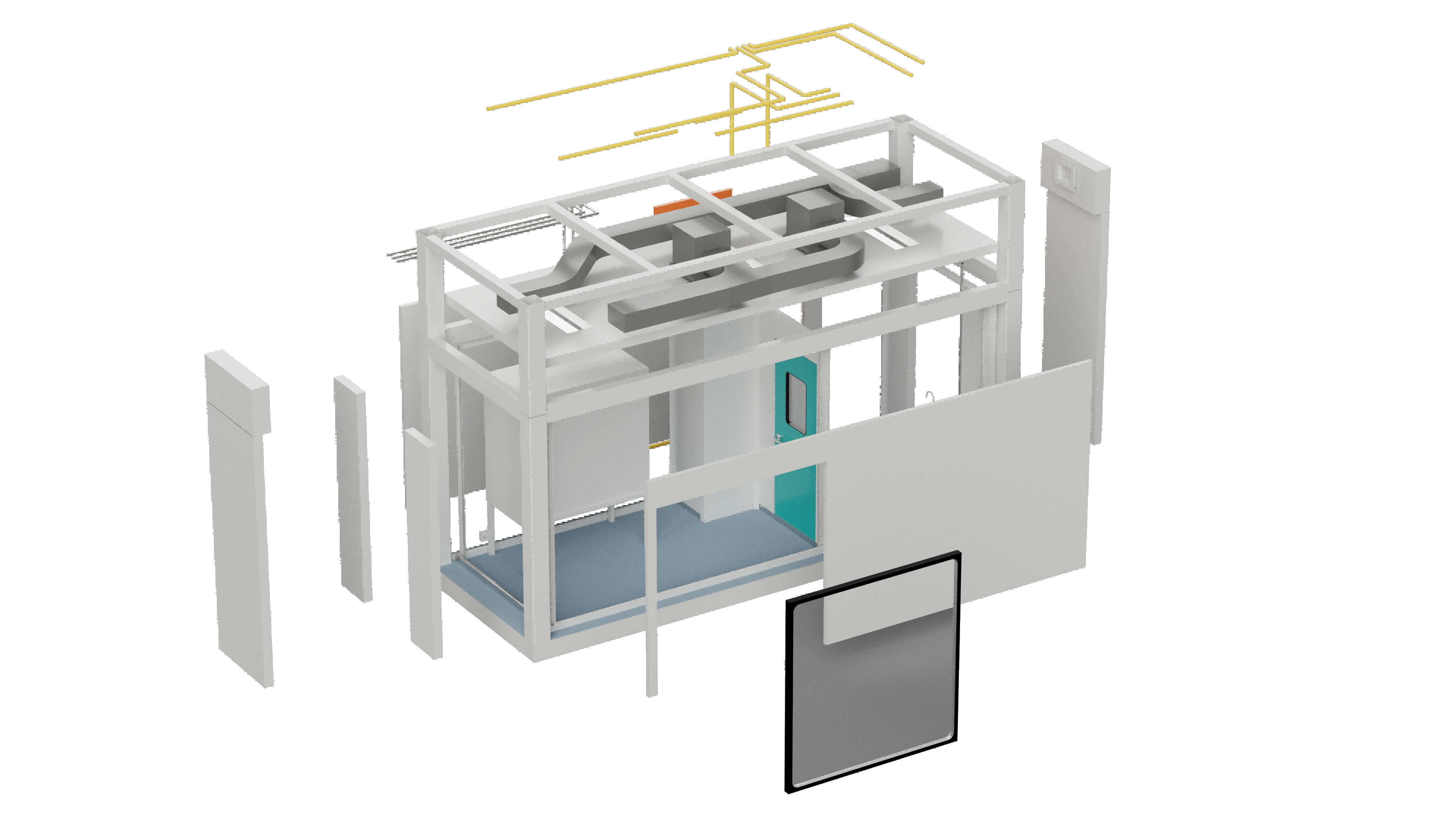

Modular cleanroom by Wiskind at CPHI Shanghai 2025

1. Flexibility & Scalability: Modular design allows for easy adjustments to a cleanroom's size, layout, and classification. Whether it's initial installation or future expansion, integration is seamless, minimizing impact on your production.

2. Rapid Deployment: Compared to traditional cleanrooms, the prefabricated components of Wiskind Cleanroom modular solutions significantly reduce on-site installation time, helping you get into operation faster.

3. Cost-Effectiveness: Streamlined construction processes and reusable components effectively lower overall construction costs and future upgrade expenses.

4. High Quality & Reliability: All modular components are prefabricated in a controlled environment, ensuring superior construction quality and cleanroom performance.

5. Easy Maintenance: The modular structure facilitates equipment integration and routine maintenance, reducing operational complexity.

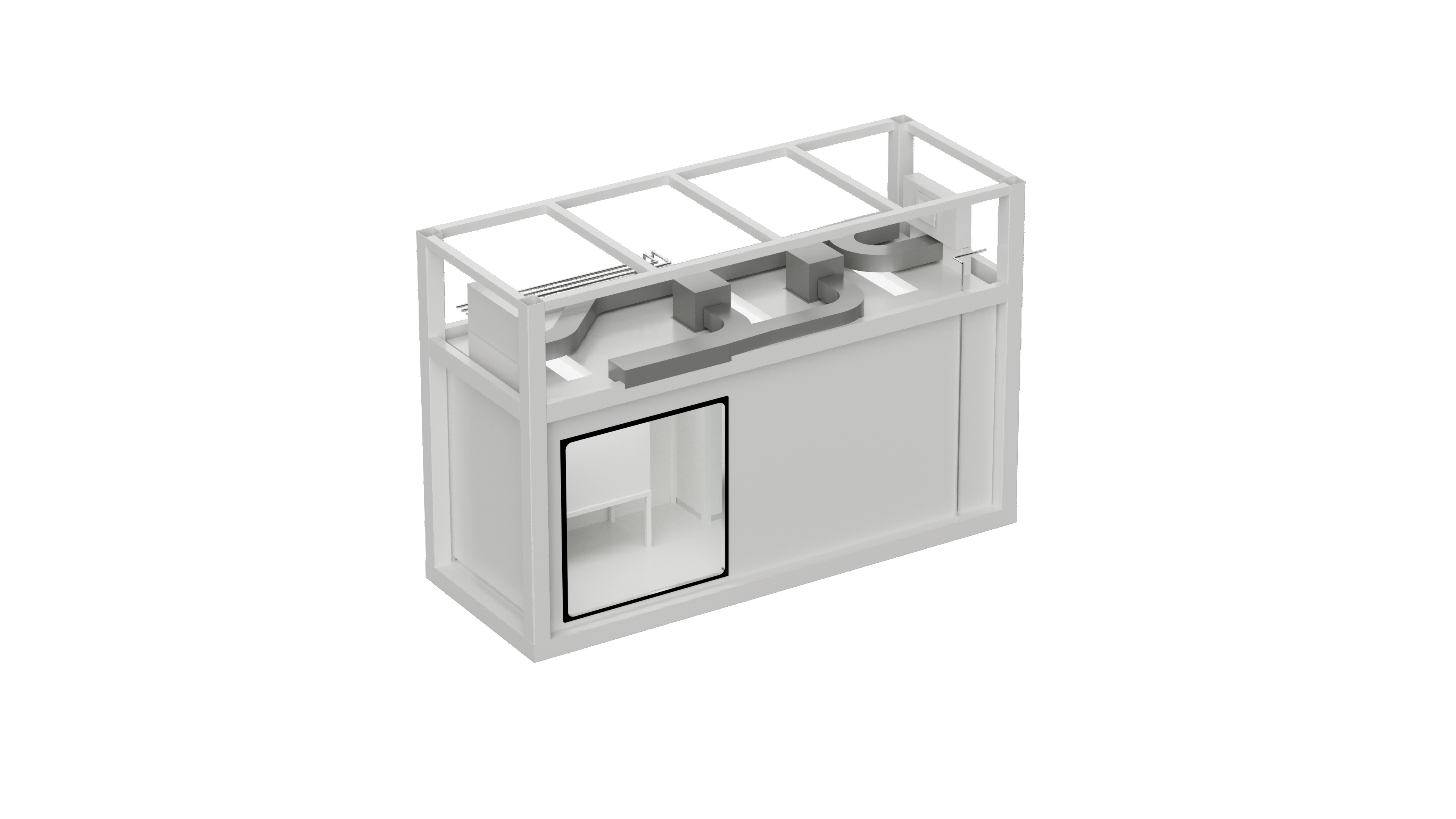

Wiskind Cleanroom offers a full range of modular cleanroom solutions, from small laboratory clean zones to large production facilities. Whether you need a compact cleanroom or a multi-zone clean system, we can provide the optimal size and configuration recommendations based on your specific site and process flow.

• Class 100 to 100k / ISO5 to ISO8 per ISO 14664-1 and FED STD 209E

• One pass or recirculating

• Temperature/Humidity environmental controls

• Standard modular or hybrid

• Custom floor plans

• Custom Height: 7.5’ to 40’

• Equipment mezzanines

• Drawings and engineering calcs for permits

• Wall surfaces: Melamine, vinyl coated gypsum, FRP, glass, polycarbonate, painted aluminum, or stainless steel

• Wall core: honeycomb, urethane, polystyrene, or aluminum honeycomb

• Doors: single, double, automatic sliding, motorized roll up, interlock systems

• Flooring: VCT, heat welded vinyl, epoxy, anti-static, and raised

• Lighting: T-8, LED, tear drop, skylight tubes

• Metal-free cleanrooms for mass spectrometer and trace metal labs

Our design team will work closely with you to consider the following factors:

1. Footprint: Optimized design based on your available space.

2. Cleanliness Classification: We can achieve classifications from ISO 8 (Class 100,000) to ISO 3 (Class 1) and even higher.

3. Personnel & Material Flow: Planning efficient and cleanroom-compliant entry and exit pathways.

4. Modular Equipment Options: Reserving interfaces and space for your production equipment.

• HEPA and ULPA fan filter units, standard and RSR

• ACS2000 power saver, ACS3000 room monitoring system: T/RH/Air pressure

• Air showers, pass thru’s

5. Future Expansion: Considering your potential growth and providing scalable solutions.

We understand the rigorous demands for cleanliness across different industries. Our Wiskind Cleanroom modular solutions strictly adhere to international and domestic industry standards, ensuring your production environment complies with all regulations. We are capable of meeting the needs of and serving the following industries:

1. Pharmaceutical & Biotechnology: Adhering to cGMP (current Good Manufacturing Practice) standards, including ISO 5 to ISO 8 classifications, ensuring sterile environments for drug production, R&D, and packaging.

2. Medical Devices: Meeting ISO and relevant cleanroom standards, suitable for the assembly, testing, and packaging of medical devices.

3. Electronics & Semiconductors: Providing high-grade cleanrooms, such as ISO 3 to ISO 6, for the manufacturing of microelectronics, optical components, and precision instruments, preventing micro-particle contamination.

4. Food & Beverage: Ensuring hygienic safety in food processing and packaging, preventing microbial contamination, and complying with HACCP and relevant food safety standards.

5. Aerospace: Providing ultra-high cleanliness environments for the assembly and testing of precision components.

6. Research Laboratories: Offering controlled clean environments for various scientific research purposes.

• Expert Consultation & Design: An experienced team provides you with customized design solutions.

• High-Quality Manufacturing: Utilizing premium materials and advanced processes to ensure cleanroom performance.

• Rapid Installation & Commissioning: A professional construction team guarantees efficient project completion.

• Comprehensive Validation & Support: Providing cleanliness testing, validation reports, and complete after-sales service.

We understand that every cleanroom project is unique. That's why we specialize in customizable, high-quality modular cleanrooms designed to meet your specific requirements. Our product range is engineered for superior performance.

Cleanroom Panels: Our cleanroom partition systems feature a variety of wall panels offering excellent performance and simple modular installation.

Cleanroom Doors & Windows: Our cleanroom doors are known for their flatness, high structural strength, corrosion resistance, and ease of cleaning, ideal for sterile environments.

Cleanroom Ceiling Systems: Designed for strong tightness, walkability, and seamless integration for a consistent aesthetic.

Comprehensive Cleanroom Equipment: We provide all essential cleanroom equipment, from efficient air outlets and FFUs to pass boxes and air showers, ensuring a complete and optimized controlled environment.

We will contact you as soon as possible!

Modular Cleanroom

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.