We have a passion for unconventional solutions that bring your vision to life.

As industries such as pharmaceuticals, biotechnology, electronics, and new energy continue to demand higher standards for clean environments, traditional construction methods struggle to meet modern requirements in terms of response speed, cost control, and spatial flexibility. Modular cleanrooms, as an innovative spatial solution, are emerging as a new trend in cleanroom construction.

1. Fast Delivery and Shorter Project Timelines

1. Fast Delivery and Shorter Project Timelines

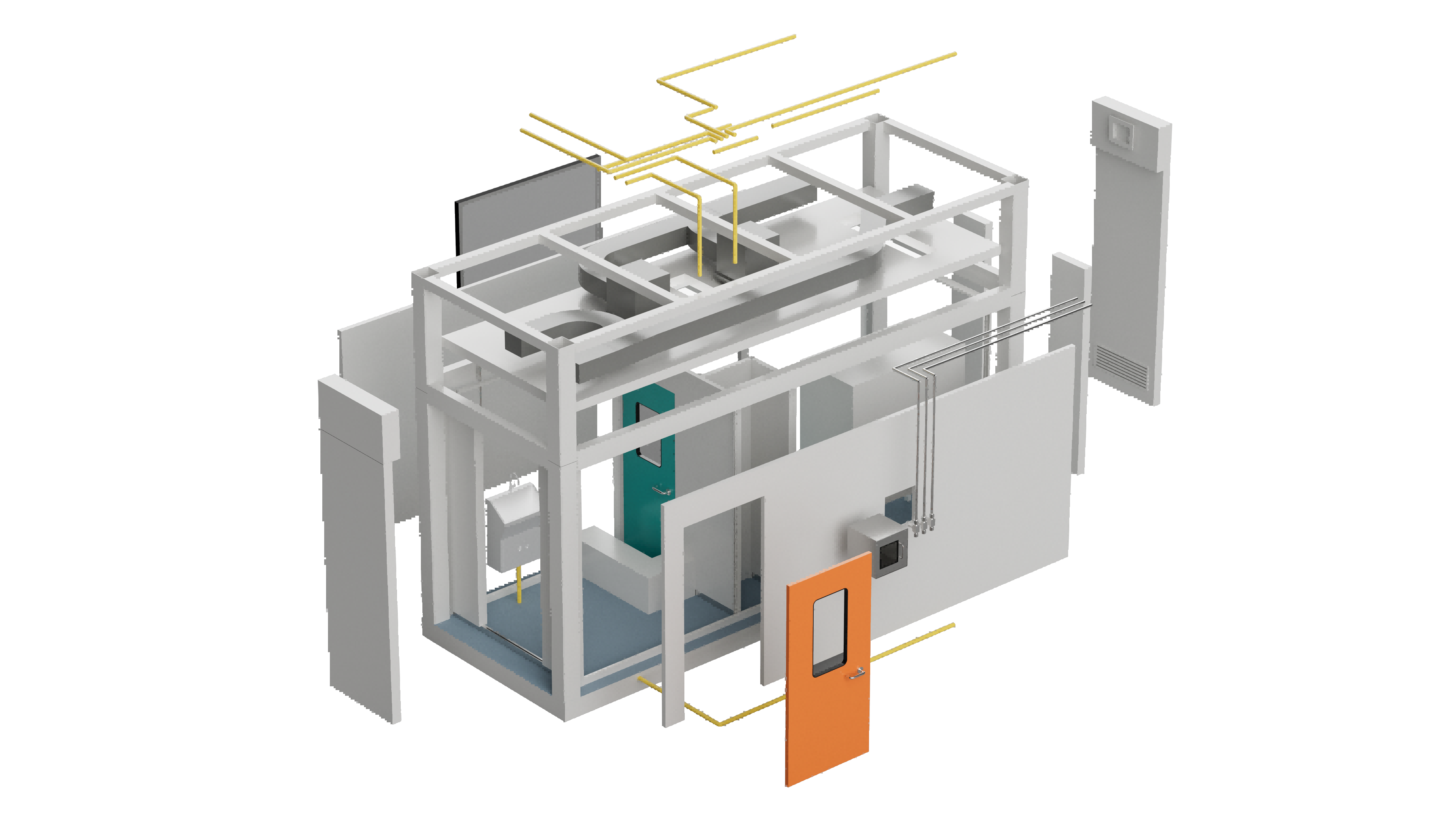

Modular cleanrooms adopt a factory prefabrication + on-site assembly model. Most structural and functional components are precisely manufactured in a controlled factory environment, greatly minimizing on-site work. Compared to conventional builds, this approach can reduce the construction timeline by more than 30%, enhancing production efficiency and accelerating time-to-market.

With standardized modular design, modular cleanrooms can be quickly deployed for both new constructions and facility upgrades. As production lines change or business scales up, users can easily expand, reconfigure, or relocate their cleanroom spaces, maximizing asset utilization and spatial adaptability.

All components are manufactured under strict factory standards, in full compliance with GMP, ISO, and other international guidelines. This ensures comprehensive control over materials, processes, and quality. On-site installation is like assembling building blocks, avoiding the complexities of traditional wet construction and minimizing contamination risks.

With high system integration, modular cleanrooms optimize HVAC performance and reduce energy consumption. Their modular structures also allow for easier maintenance and part replacement, lowering long-term operating costs. Many materials are recyclable, supporting sustainable, eco-friendly development goals.

Built on standard modules, modular cleanrooms can also be customized to meet specific client requirements—accommodating various cleanroom classifications, airflow patterns, and integrated equipment needs. They are widely applied in high-spec clean environments such as pharmaceuticals, biopharmaceuticals, semiconductor electronics, medical devices, and new energy industries.

Modular cleanrooms are ushering in a new era of cleanroom construction—more efficient, more intelligent, and more sustainable. Beyond being an innovative building method, they are a powerful driver for enhancing enterprise competitiveness and accelerating industrial transformation.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.