We have a passion for unconventional solutions that bring your vision to life.

The launch ceremony of Wiskind’s third cleanroom panel full- automatic production line and conference that pledging to re-improve the production quality was held successfully On June 6, 2022, Members participating in the ribbon-cutting ceremony of Wiskind Clean Technology 's leadership team as the following:Yang Fuchang,General manager,Wang Lingshan, vice president of operations,Gao Jun, vice president of intelligent manufacturing DEPT,Guo Qingchen,Sales Center Director,Wei Jianlong, director of technology R&D Center,Li Jia,Production director

New Production Line / New Appointment / New Breakthrough

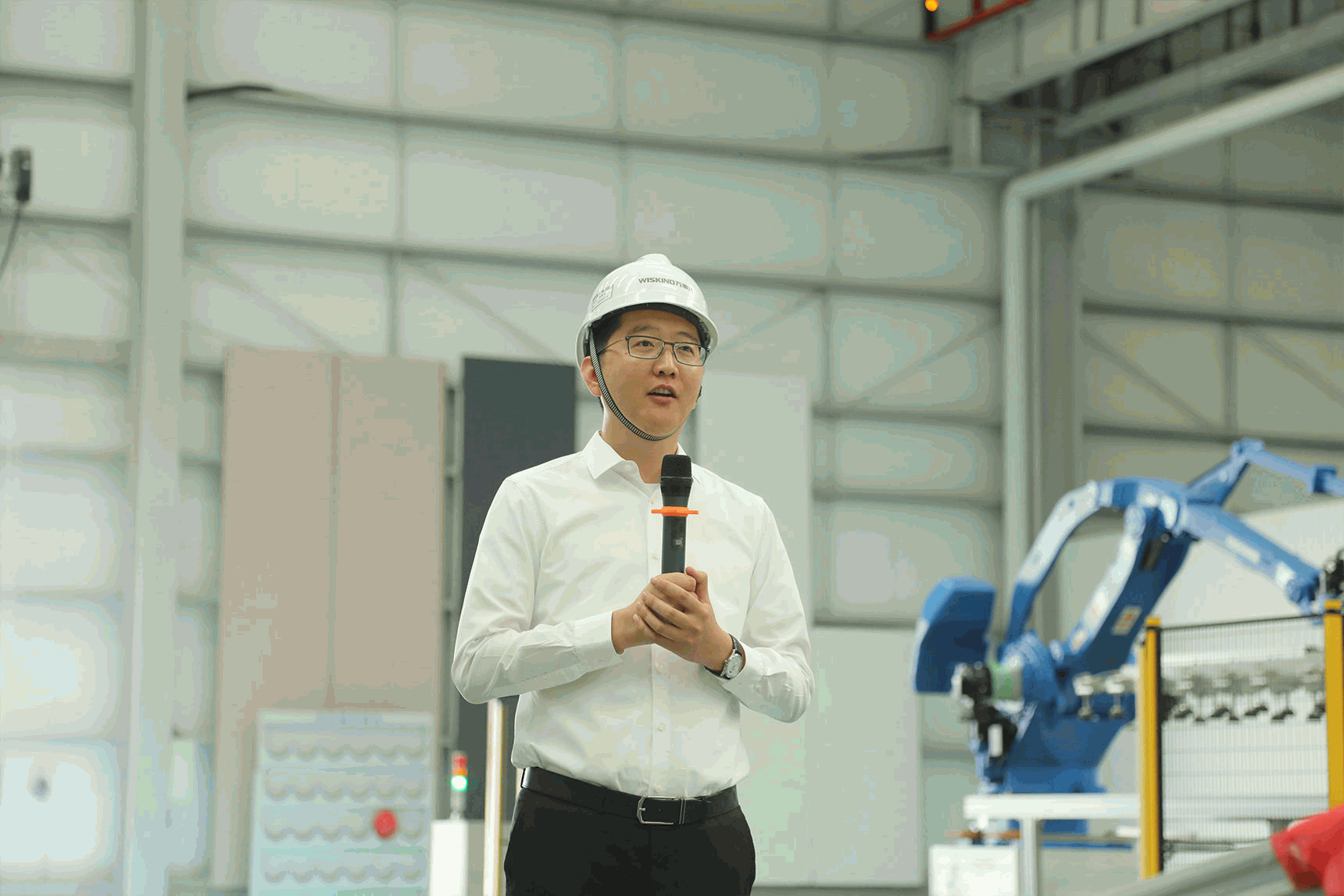

Yang Fuchang, General manager of Wiskind Clean Technology Co.,Ltd said: "The fully automatic production line will set a new record for the industry's production scale, production efficiency and production technology, and will promote the industry to a higher standard. We must adhere to the implementation of more stringent quality standards, output higher quality products for customers is our value goal. Being a respected and sustainable company is our vision.

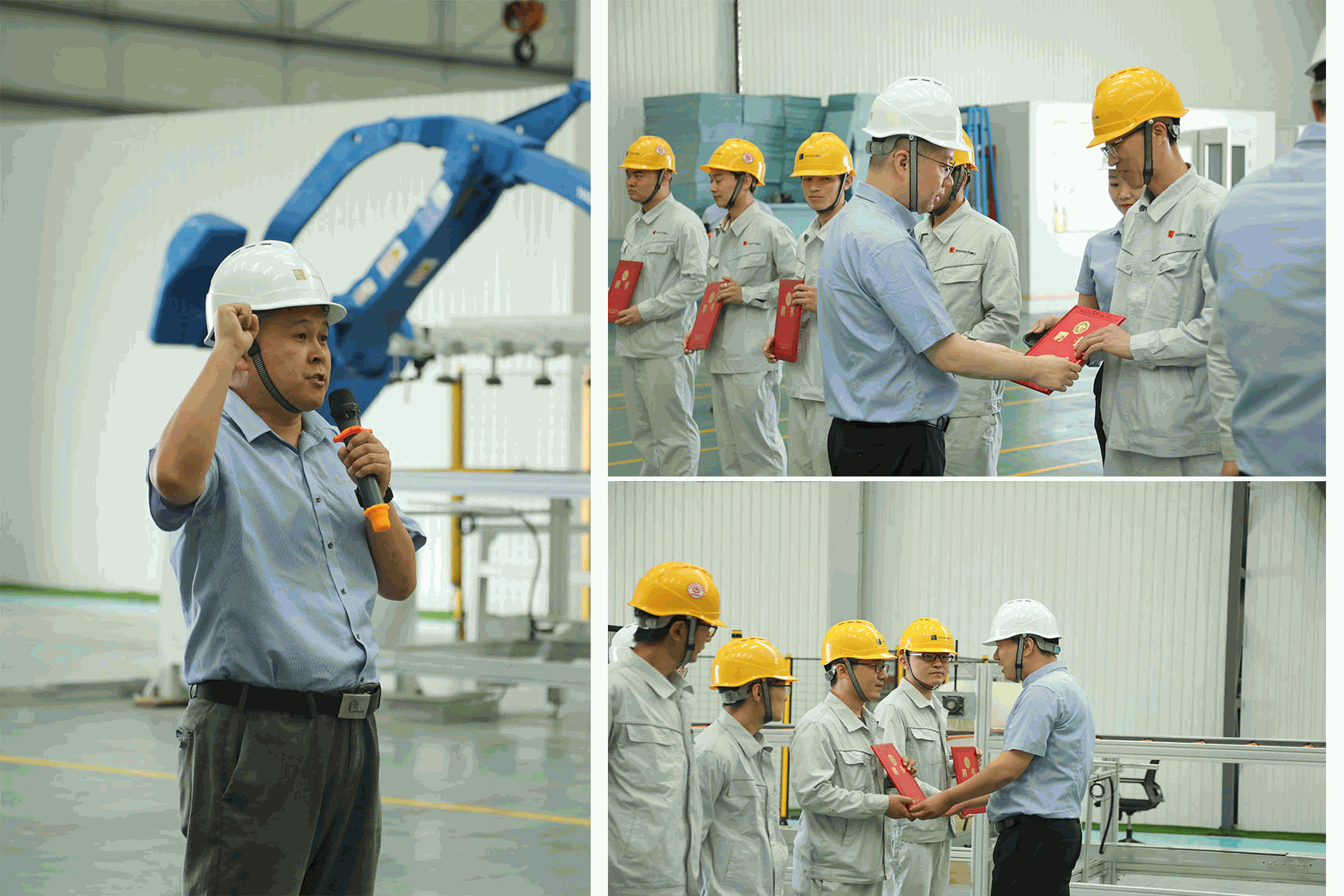

Gao Jun and Li Jia as the production director, issued the letter of appointment for the newly team leader , QC manager Zhang Yong led everyone to pledge quality.

Digitization enables high-speed cleanroom production

The new cleanroom panel automatic production line is independently developed by Wiskind, which is an important milestone for Wiskind to move towards high-end manufacturing and lead the rapid development of the cleanroom industry.

The new production line introduces the world's most advanced automatic production equipment which imported from Italy. Compared with the traditional cleanroom panel production line, the production efficiency is increased by 6-8 times.

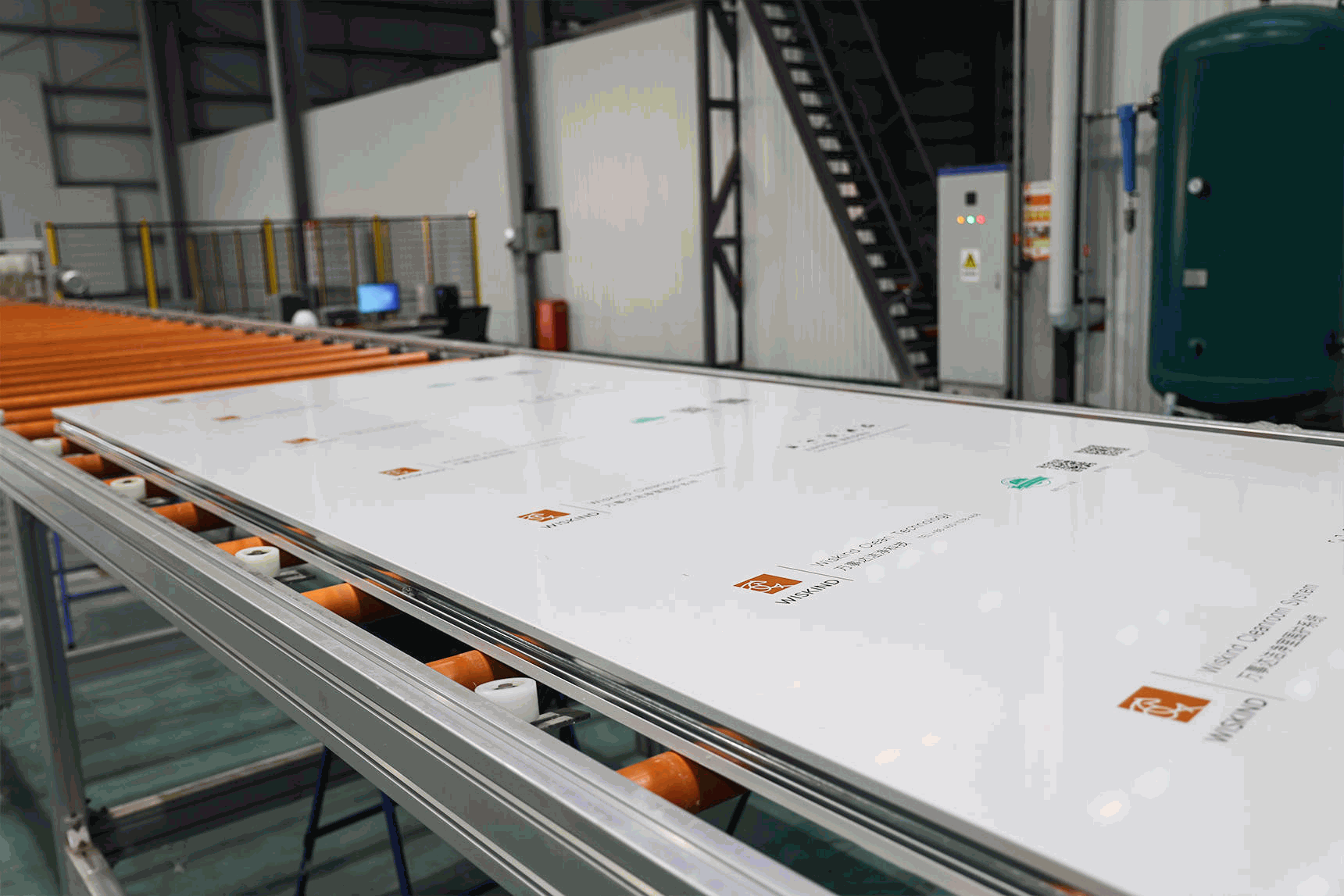

The production line includes seven major processes: steel board rolling and forming, automatic cutting of core material, automatic gluing, automatic rockwool refilling, material compounding-hot pressing and palletizing.

The system has the characteristics of high degree of automation, fast processing efficiency and stable product quality. The maximum production capacity is increased to 5 million square meters per year, and it can produce a variety of core material cleanroom panel. The continuous production system of cleanroom panel has reached the international advanced level.

Innovative technology, soaring the sense of product superiority

1.High precision composite

The new process sheet is compounded from the inside of the high-precision compound machine, and there are side molds on the side of the sheet for clamping and positioning during compounding.

2.Higher cleanliness and flatness

In terms of flatness and lateral verticality of the board surface, the new equipment adopts a single-piece board pressing process, and the upper and lower parts of the material are pressed by a single piece of steel mold, which has high flatness and avoids the moon bend, distortion and deformation that occurs in multi-layer pressing.

3.Lateral verticality is straighter

The side molds are set laterally to be fixed to ensure the lateral verticality, which completely avoids the dimensional error caused by the displacement of the upper and lower steel plates when they are composited, and ensures the accuracy of the panel seam after installation.

4.The thickness of the cleanroom panel is consistent

The thickness of the Panel is positioned by the thickness of the block on the side, and the thickness consistency of the panel after composite is same, which avoids the unevenness of the panel surface after installation.

5.Sparying Adhesive Automaticly

Adopting adhesive "rooted" technology, quality is more stable.Through experimental data detection, automatic production line products compared with the industry excellent traditional manual production line, the bonding strength and bending capacity have been greatly improved,the rock wool cleanroom panel bonding strength of automatic production line is 50% higher than that of excellent traditional manual production line in the industry.

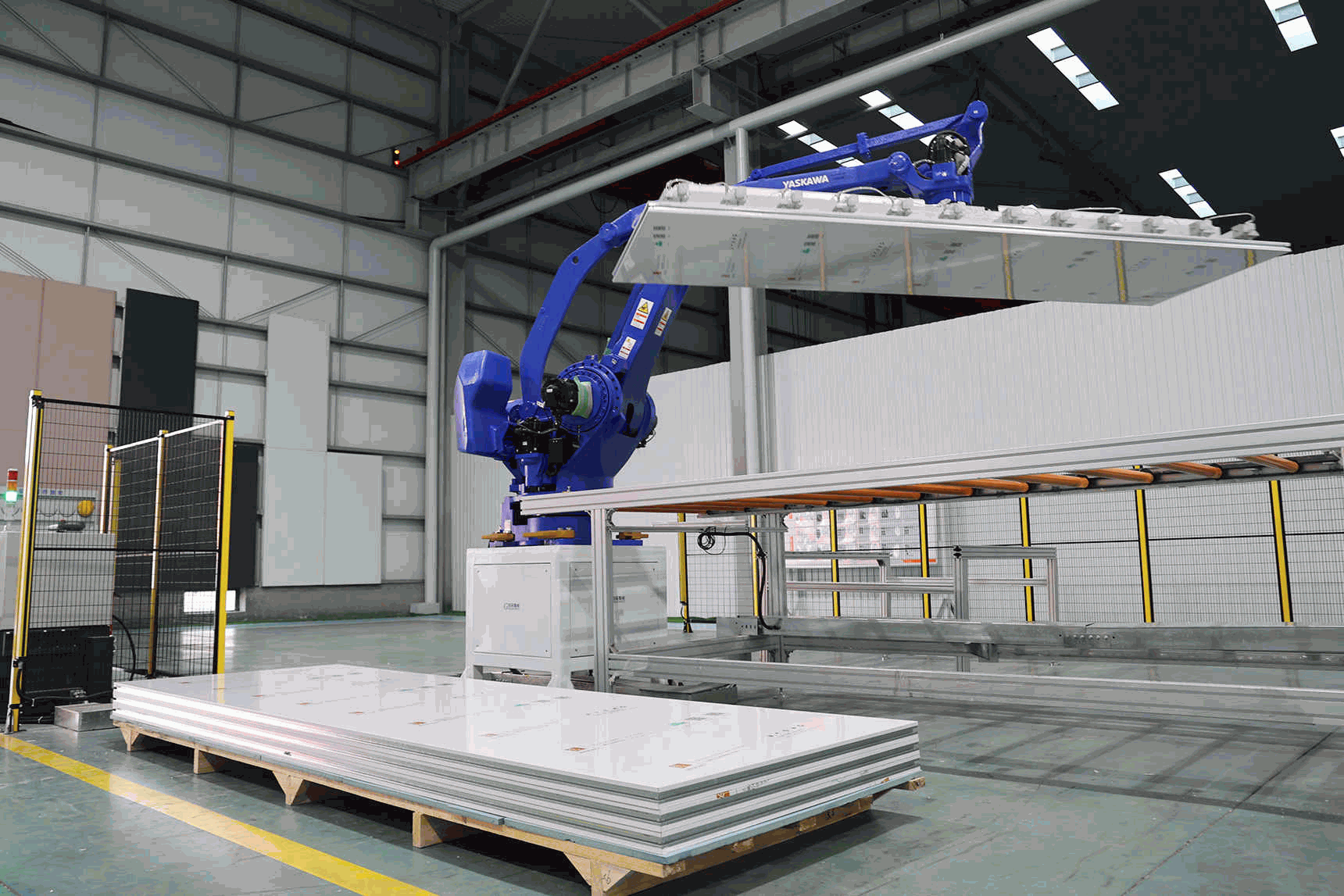

6.Robotic palletizing

Using fully automated robots for palletizing, so more efficient. Through accurate measurement and intelligent control, the precision, strength, flatness and beauty of the cleanroom panel are greatly improved, and the product quality is more stable.Truly achieve "science and technology to make each cleanroom panel quality is the same"

Create a better future for WISKIND

WISKIND's new cleanroom panels automatic production line has been put into full production, which will become one of the core competitiveness of Wiskind, and will develop towards a more efficient, more scientific and more friendly direction for the field of clean room enclosure systems.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.