We have a passion for unconventional solutions that bring your vision to life.

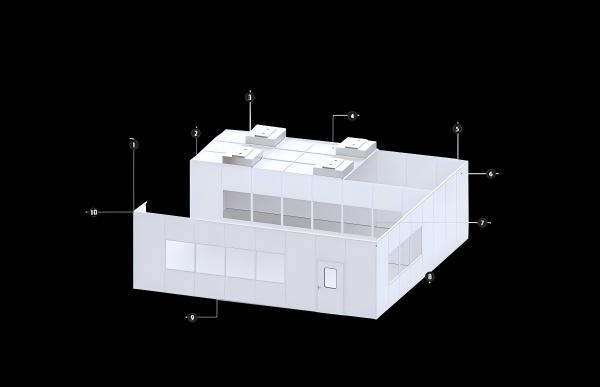

Clean rooms play a vital role in various industries, from pharmaceuticals to technology, ensuring a controlled environment that minimizes contamination. The integrity of these environments is essential to maintaining product quality and safety. This article explores comprehensive strategies for maintaining cleanroom integrity, focusing on daily maintenance routines, cleaning protocols, inspection checklists, repair guidelines, and downtime minimization. Whether you're managing a pharmaceutical clean room or a semiconductor cleanroom, these insights aim to provide clear and actionable guidance.

Establishing rigorous daily maintenance routines is crucial to uphold the standards of any cleanroom. The primary objective is to prevent contaminants from compromising the controlled environment. Cleanroom solutions should be tailored to specific operations, considering the cleanroom classification that applies, such as ISO cleanroom classifications.

Ensure all operators follow strict dress codes, utilizing properly certified apparel to maintain the required clean room levels.

Audit cleanroom construction to assess the condition of clean room panels and ensure there is no structural compromise.

Maintain optimal functionality of equipment, such as the Fan Filter Unit (FFU), which is crucial for sustaining air quality within the cleanroom environment.

One must be proactive about identifying potential breaches in cleanroom barriers. It's recommended to use advanced sensors to monitor air quality and carry out frequent air changes as required by the class 100 clean room and other relevant standards. Regular maintenance of lights, clean room doors, and HVAC systems should also be performed to ensure a sterile environment.

Effective cleaning protocols are integral to maintaining cleanroom integrity. These cleaning routines should adhere to the prescribed ISO clean room classification, be it ISO 7 cleanroom or class 10000 clean room, ensuring a sterile working environment is consistently achieved.

Protocol | Frequency | Key Focus Areas |

Surface Wiping | Daily | Workstations, equipment surfaces |

Floor Cleaning | Twice Daily | High-traffic areas |

Laminar flow hood Cleaning | Weekly | Interior and exterior surfaces |

Full Facility Sanitation | Monthly | All structural components |

Cleanroom equipment must be regularly sanitized using correct chemical solutions that do not introduce new contaminants. Using specialized tools like swabs and wipes designed for cleanroom use can prevent material shedding and further contamination.

Thorough inspections are vital to maintain the cleanliness and operational standards of any cleanroom. An inspection checklist should be implemented, identifying key areas that need frequent assessment based on the clean room classification.

Here are common elements to include in a cleanroom inspection checklist:

Assess the integrity and cleanliness of coolroom panels and cleanroom wall panels.

Check the operation of the air shower and hepa fan filter unit.

Verify the function of cleanroom doors and ventilation systems to maintain adequate airflow and pressure.

Routine inspections help identify any risks or failures before they escalate into significant downtime occurrences. Maintaining a record of inspections can help cleanroom managers understand trends and devise strategic measures for consistent improvement.

Prompt repairs ensure the cleanroom's dependability and adherence to the expected cleanliness levels. A structured approach to repairs helps maintain these sensitive environments efficiently.

Repair guidelines typically include:

Documenting ISO clean room classification issues to address needs specific to standards like ISO 6 cleanroom and ISO 8 cleanroom.

Executing repairs with certified cleanroom constructors to ensure any modifications meet cleanroom protocols.

Regular checks of systems like the fan filter unit for clean room to pre-empt any operational limitations.

Engaging with certified professionals for cleanroom validation ensures that standards are not compromised post-repairs. Prioritizing minimal contamination during repairs is critical in preserving the cleanroom manufacturing processes.

Minimizing downtime is fundamental to maintaining operational efficiency and cleanroom integrity. The goal is to keep interruptions to a minimum, especially in a semiconductor cleanroom or pharmacy clean room setting, where even a minor disruption can impact production significantly.

Strategies for reducing downtime include:

Implementing an advanced notification system that alerts staff of potential equipment failures.

Investing in modular cleanrooms that allow for quick adjustments and minimized disturbance during necessary upgrades or repairs.

Conducting regular maintenance and repairs proactively to prevent unexpected breakdowns.

Reducing downtime not only supports productivity but also maintains the optimal cleanroom environment, ensuring that processes like semiconductor cleanroom manufacturing and pharma clean room operations remain uninterrupted.

Maintaining cell cleanroom integrity is essential for ensuring product quality and operational efficiency across industries. Through rigorous maintenance routines, ISO clean room classification adherence, insightful inspection checklists, comprehensive repair guidelines, and effective downtime minimization strategies, one can uphold the standards necessary for optimal performance. Cleanroom managers and operators must stay up to date with innovative practices and technological advancements to ensure these environments meet ever-evolving industry demands.

For more in-depth resources on cleanroom maintenance and management, consider exploring leading industry sources and collaborating with expert cleanroom constructors.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.