We have a passion for unconventional solutions that bring your vision to life.

As a special space that controls environmental factors such as air cleanliness, temperature, humidity, and pressure, clean rooms are widely used in industries such as pharmaceuticals, electronics, food, and bioengineering. Among them, the sandwich panel serves as the core component of the clean room's enclosure structure, directly affecting the stability and reliability of the clean environment. Sandwich panels not only play roles in insulation, soundproofing, heat preservation, load-bearing, and isolation but also require good performance in fire resistance, anti-static, antibacterial, and corrosion resistance. Depending on the core material and surface material, clean room sandwich panels can be divided into various types. This article will introduce several common types of sandwich panels in detail based on their material characteristics and application areas.

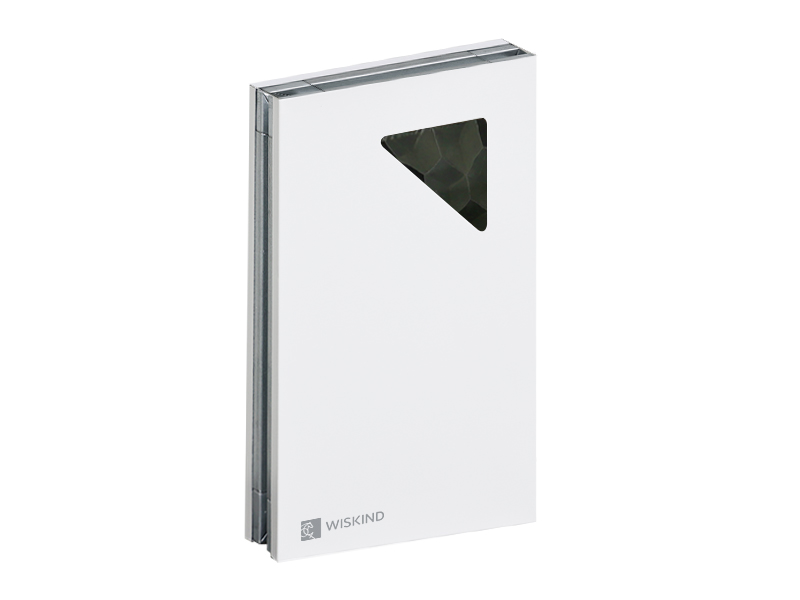

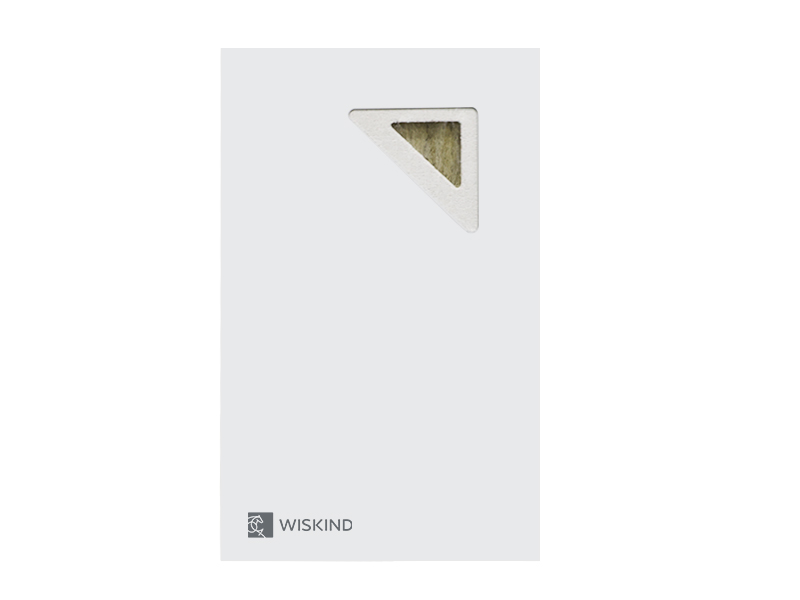

Rock wool is an inorganic fiber material made mainly from basalt. It has good fire performance (Class A non-combustible), thermal insulation, and soundproofing effects. Its structure is compact and strong, making it one of the most widely used fire-resistant sandwich materials in clean rooms. Rock wool sandwich cleanroom panels are suitable for places with high fire resistance requirements, such as pharmaceutical workshops and chemical laboratories. However, due to its strong hygroscopicity, proper sealing and moisture-proof treatment are necessary.

Polyurethane foam core material has a low thermal conductivity, excellent thermal insulation performance, light weight, and high strength. PU sandwich panels are mainly used in clean spaces with high requirements for thermal insulation, such as electronics factories and low-temperature storage areas. However, its fire resistance is poor, usually requiring the addition of flame retardants, and it tends to age in high-temperature environments.

The paper honeycomb core material is composed of multiple honeycomb structures, offering good flatness, light weight, high strength, and low cost. Its overall structure is stable, commonly used for non-load-bearing walls in removable wall panel system with low load requirements, suitable for electronics, laboratories, and other spaces where the cleanliness level is not particularly high. Its disadvantages are relatively weak moisture and fire resistance.

Aluminum Honeycomb Sandwich Panel

Aluminum honeycomb panels use aluminum plates as surface material and aluminum honeycomb as core material, offering multiple advantages such as light weight, high strength, good seismic performance, strong non-combustibility, and corrosion resistance. They are an ideal choice for high-end clean rooms. Their surface can be treated for anti-static and antibacterial properties, suitable for industries like semiconductors, aerospace, and biopharmaceuticals. Although the cost of aluminum honeycomb sandwich panels is high, their superior performance makes them recognized for cost-effectiveness by many companies.

Magnesium oxide board is an inorganic material with good fire resistance, moisture resistance, antibacterial, and anti-aging properties. It is usually combined with rock wool, honeycomb materials, etc., to enhance the overall structural strength and cleanliness performance. Magnesium oxide board sandwich panels are commonly used in pharmaceutical clean rooms and laboratories, especially suitable for environments with high antibacterial requirements.

Summary

There are numerous types of clean room sandwich panels, each material having its own strengths in fire resistance, insulation, antibacterial properties, and strength. Choosing the right sandwich panel should not only consider functional needs but also comprehensively evaluate the actual application scenario, cleanliness level, and budget. As cleanroom technology continues to advance, sandwich panel products are also continuously optimized, moving towards more intelligent, environmentally friendly, and high-performance development. Selecting the right sandwich panel is the first step in creating an efficient, safe, and reliable clean environment.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.