We have a passion for unconventional solutions that bring your vision to life.

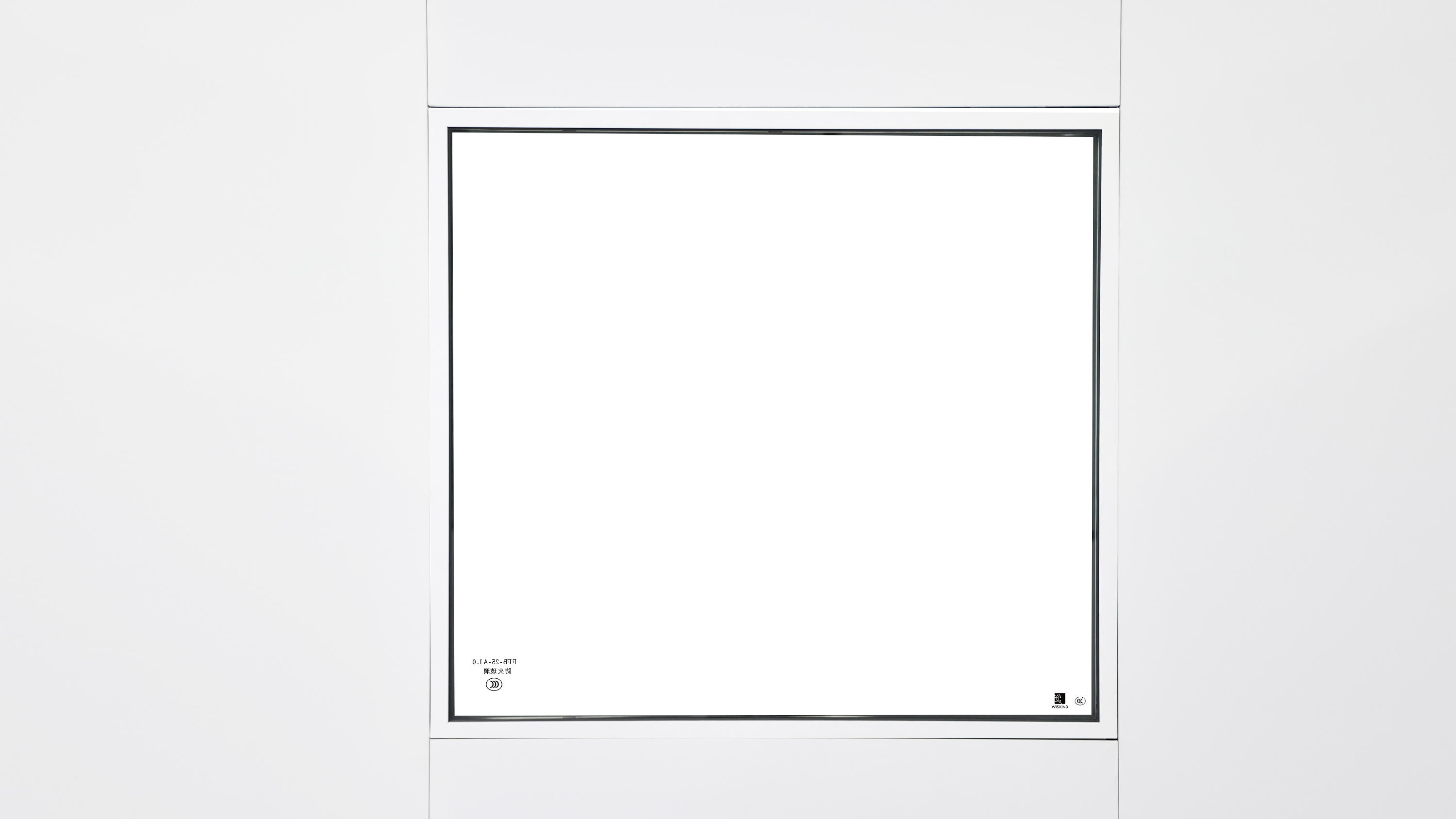

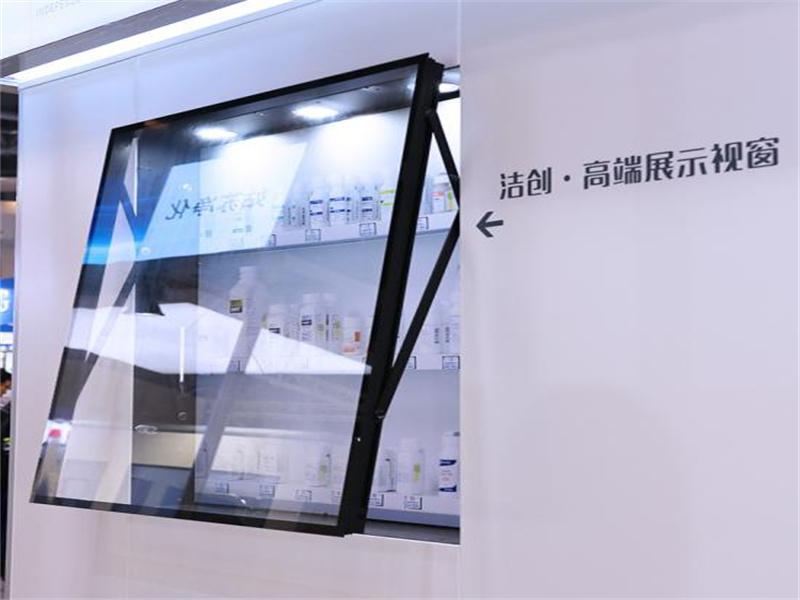

Cleanroom Doors & Windows

Wiskind cleanroom doors widely used in cleanroom / sterileroom for workshops, hospitals, pharmaceutical factories, food factories, etc. They has good performance in flatness ,high structural strength, corrosion resistance, no dust, easy to clean. Wiskind cleanroom doors and windows are engineered for your advanced manufacturing industry.

A: Clean room classifications are generally denoted by grades, where higher grades signify greater cleanliness levels. In hospital settings, the prevalent grades include Class 100,000 (equivalent to ISO 8), Class 10,000 (ISO 7), and Class 1,000 (ISO 6). These are well-suited for hospital uses like operating rooms, sterile processing areas, and laboratories. Cleanroom doors are specifically engineered to comply with the standards of their designated class. For instance, a door for clean room in Class 100,000 incorporates smooth surfaces, secure seals, and automatic closing features to block contaminants. Cleanrooms doors for a Class 10,000 clean room require stricter standards, including enhanced airtightness and reduced outgassing to preserve room purity.

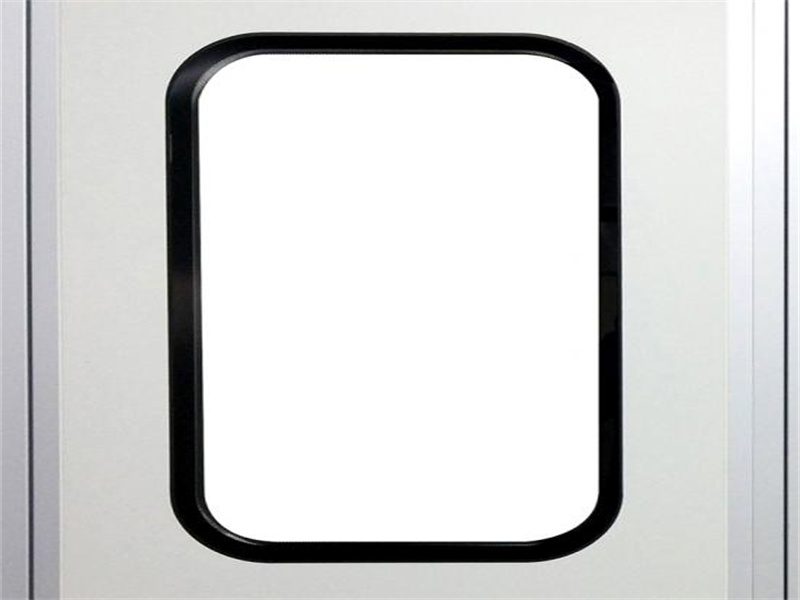

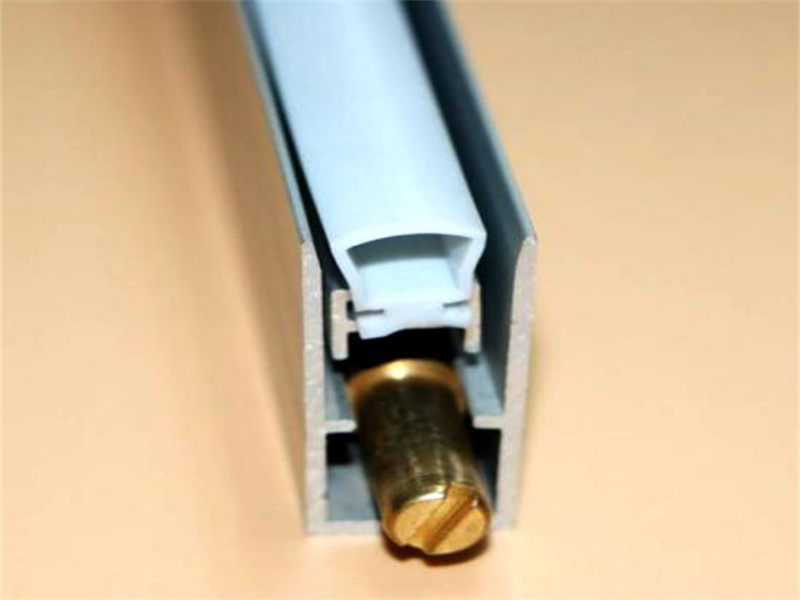

A: Cleanroom doors indeed incorporate numerous specialized features to uphold the clean room's controlled conditions. These can encompass airtight seals to block contaminants, interlocks that stop simultaneous door openings, and automatic closing systems to keep doors shut consistently. Some doors also feature integrated filters or air purification mechanisms to lower contaminant levels further, along with antibacterial coatings or treatments for resistance against microbes. Various suppliers offer these capabilities, and Wiskind provides a comprehensive selection of tailored cleanrooms doors functions.

A: Cleanroom doors differ significantly from ordinary entry doors as they are designed for controlled environments with airtight sealing to avoid air leaks and contamination risks. Constructed from materials like stainless steel, fiberglass, or aluminum, they offer durability and simple maintenance. Key distinguishing features include seals and gaskets that eliminate gaps for air or dust passage, keeping the space free of pollutants. Interlocks prevent doors from opening during vital operations, which is crucial in medical and pharmaceutical settings for consistent conditions. Electromagnetic locks provide added security against unauthorized entry and ensure doors remain closed as required. Together with robust material builds, these elements support the sterile conditions needed for delicate operations.

A: Cleanroom doors come in diverse types and materials to address varied industry demands. Options include steel doors, favored for their strength in pharmaceutical and medical facilities; HPL (high-pressure laminate) doors, which resist stains and scratches for frequent cleaning areas; galvanized steel doors, ideal for humid or chemical-exposed environments due to corrosion resistance; glass doors, used in labs or hospitals for visibility with containment; and aluminum frame doors, lightweight and corrosion-resistant for electronics and high-tech settings. Styles also vary, such as swing doors for high-traffic access with security, and automatic sliding doors for convenience in sterile medical areas where hands-free operation is preferred. Each variant, including a door for cleanroom in specialized setups, is customized to meet particular applications and industry compliance.

A: In healthcare and pharmaceuticals, where sterility is paramount, clean rooms support critical tasks like vaccine production, sterile device manufacturing, and advanced research, with any contamination risking product quality and patient health. Clean room door systems are essential in blocking airborne pollutants from entering or escaping these zones. In operating rooms or ICUs, they help sustain aseptic conditions to avoid infections and support successful procedures. In bio-pharmaceutical plants, they prevent raw material contamination that could lead to severe consequences. Through airtight seals, resilient materials, and features like interlocks, these doors safeguard the high-stakes integrity of such environments.

A: Cleanroom doors extend to various sectors outside healthcare and pharmaceuticals. In food and beverage production, they block contaminants and allergens from entering manufacturing zones, especially for health-focused or allergen-free items. In electronics manufacturing, they protect microchips, semiconductors, and components from dust that could cause failures. In cosmetics production, they maintain bacteria- and dust-free conditions to preserve product purity. Each industry demands specific door attributes in durability, cleanability, or functionality to align with operational needs, ensuring a reliable clean room door meets regulatory standards.

A: In fields where contamination poses major risks, proper clean room door systems not only ensure cleanliness but also boost efficiency and safety. Automatic sliding doors facilitate smooth access and minimize manual interaction, while interlocks and electromagnetic locks restrict entry to authorized individuals in controlled areas. These doors also stabilize internal conditions by averting air and temperature changes that might disrupt processes. Implementing suitable systems lowers contamination risks, maintains product integrity, and shields workers from hazards.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.