We have a passion for unconventional solutions that bring your vision to life.

1. Overview of negative pressure ward and ICU in Wuhan Vulcan Mountain Hospital

Wuhan Vulcan Mountain Hospital was built to treat newly diagnosed patients with new coronary pneumonia. A total of 1,000 beds were designed for negative pressure wards, which consisted of multiple independent ward buildings. Each ward was converted with a container, with 1-2 beds. Air supply and exhaust systems are set in each ward to maintain negative pressure operation. The ICU is constructed of steel structure and color steel plate. It is divided into two areas. Each area is provided with 15 ICU beds. The two areas have a total of 30 beds. The purification level is 100,000. A new wind and full exhaust system are installed. , Medium and high efficiency filtering, through the reasonable setting of new exhaust vents and the control of room pressure gradients, to ensure the safety of medical staff, exhaust air is discharged to the roof more than 2 meters through three levels of coarse, medium and high efficiency filtering, to eliminate Environmental impact.

2. Functional partition

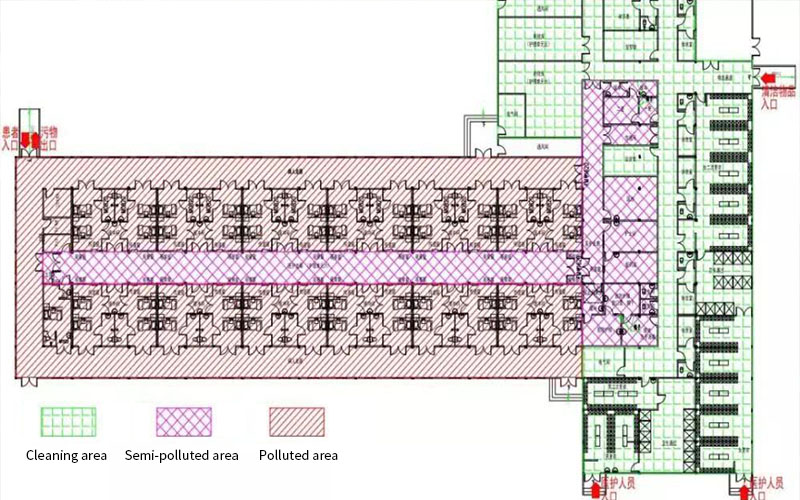

The floor plan of the negative pressure ward and ICU should be divided into clean areas (general work area, including medical lounge, consultation room and other functions), semi-polluted areas (auxiliary prevention and control area, including nurse station, treatment room, treatment room) And other functions), pollution areas (prevention and control areas, including wards, health and other functions), buffer zones should be set up between each area, and maintain a differential pressure to avoid direct air convection and pollute other areas.

1. The functional division of negative pressure ward is shown in the figure below:

2.The negative pressure ICU function zone is shown below:

3. the basic requirements of decorative professional design and key difficult solutions

(I) Basic design requirements

1. Negative pressure ward and ICU process design

1.1 Negative pressure ward area adopts double gallery design to ensure doctor-patient shunt;

1.2 Minimize the frequency of medical personnel entering the polluted area.

(1) An observation window is set up between the negative pressure ward and the medical care corridor for the monitoring of medical staff;

(2) A double-door interlocking pass box is set between the negative pressure ward and the medical care corridor to transfer meals;

2. Negative pressure ward and ICU material configuration

2.1 The cleanroom wall surface and top surface should be high-quality cleanroom panels that do not produce dust, are easy to clean, corrosion-resistant, scrubbing with disinfectant, collision-resistant, moisture-proof, mildew-proof, and fireproof.

2.2 The floor should be non-slip, wear-resistant, acid and alkali resistant, easy to clean rubber coils or PVC.

2.3 Air-tight cleanroom doors should be used in the negative pressure ward polluted areas and semi-polluted areas, and all inner and outer windows should be double-sealed windows; the corridors passed by patients should be equipped with anti-collision belts, and all positive corners should be equipped with anti-collision protection corners.

(Ⅱ) the key and difficult points of decorative design and their solutions

Important point 1: ensure the cleanliness and tightness of the room In the construction of polluted and semi-polluted areas, the airtightness of the indoor air and the protection of air flow organization are often affected due to the tightness of the envelope structure, and it is easy to cause the spread and spread of disease microorganisms.

Solution: All gaps and holes in the surrounding walls, ceilings, floors and other surrounding structures in the contaminated area and semi-polluted area of the negative pressure ward should be strictly sealed; all clean doors and windows in the area should be sealed.

Important point 2: ensure that there is no dust accumulation in the room It is easy to cause the secondary flying of the accumulated dust due to the air flow in the room, which affects the cleanliness.

Solution: Negative pressure ward should minimize hygienic dead corners and prevent ash accumulation; except for common working areas, the corners of all corners should be rounded for cleaning and disinfection.

Important point 3: Ensure that the room does not breed bacteria

How to ensure that indoor decoration materials do not breed bacteria is also an important content of the construction of negative pressure wards.

Solution: The interior decoration should be made of non-bacteria materials. Glass glue and silica gel that are prone to mold should be avoided in all restricted areas. All sealants should be free of irritating volatiles, aging resistance, corrosion resistance, and antibacterial properties. Neutral material.

Important point 4: Ensure proper humanized design

The construction of traditional negative-pressure wards often neglects the creation of an indoor atmosphere, which is permeated with tension and depression, which is not conducive to the rehabilitation of patients and the relief of medical staff's work pressure.

Solution: The location design of the negative pressure ward should fully consider natural lighting; the ceiling height should be 2.8 meters to prevent the space from being too small to feel depressed; the indoor color matching should be warm and bright; the ward should be equipped with closed circuit television; the overall decoration should fully consider human nature It can relieve the soothing and soothing effects of medical care and patients' emotions.

4. the basic requirements of HVAC professional design and key and difficult solutions

(I) Basic design requirements

1. Negative pressure ward, negative pressure ICU and other recommended purification levels are 100,000.

2. The ward adopts a new air system, that is, full delivery and full row. The buffer room and toilet supporting the ward are integrated into the ward air-conditioning system.

3.Each set of negative pressure ICU is equipped with a set of air supply and exhaust system, the air supply unit is equipped with G4 + F8 filter device, and the indoor air supply port uses built-in H13 high-efficiency air supply port for air supply. Exhaust fan set is equipped with G4 + F8 + H13 filtering device.

4. The exhaust fan units are all equipped with standby units, one for each use and one for backup.

5. The purification unit is equipped with electrodes / electric humidifiers for humidification. The cold and heat sources are provided by air-cooled module units. When the number of units is small and there is no dedicated room on site, an integrated direct expansion purification unit can be used.

(II) Major and Difficulties in HVAC Design and Solutions

Point 1: Guarantee of indoor cleanliness and temperature and humidity

The air-conditioning air purification system adopts three-stage filtration (coarse, medium, sub-high / high-efficiency filters). The new air system table cooler configuration can adopt water table cooling + fluorine table cooling dual table cooling form. Steam humidifier is preferred, plus high precision Control system to ensure indoor cleanliness, temperature and humidity can be controlled.

Priority 2: Ensuring a Safe Working Environment for Medical Staff

(1) The air-conditioning system of the ward adopts a new type of DC air supply system. All indoor air is exhausted and is not recycled.

(2) Negative pressure ward adopts the upper and lower exhaust flow groups, and the air flow direction is single and not disordered.

(3) Targeted airflow organization. The layout of indoor air supply and exhaust vents is as shown below. The air flowing through the patient does not go through medical care to ensure the safety of medical personnel.

Point three: ensuring the safety of the external environment

(1) Reasonable pressure gradient, the polluted air in the ward will not overflow, and the polluted air in the outdoor will not intrude, and static isolation is achieved.

(2) Exhaust air system filtration is very important to the safety of the ward environment. High-efficiency filters are installed in the exhaust air outlets of the ward, and the leak detection of the filters can be implemented to block all pollutants indoors to ensure that the outdoor environment and even the ventilation ducts are not polluted. .

(3) The exhaust air outlet is set at more than 3 meters in the highest position of the building to ensure that the exhaust air can be fully diluted into the ambient air flow, which will minimize the impact.

Point 4: Ensure constant negative pressure and pressure gradient

(1) Negative pressure is the basis of the negative pressure ward. While ensuring that the supply air volume meets the purification requirements, set a certain margin for the system air flow volume, and that the blower and exhaust air flow are equipped with variable frequency adjustment to adjust the air volume in real time according to actual needs To ensure that indoor negative pressure can still be guaranteed under the influence of multiple factors.

(2) Adopt advanced construction technology for the envelope structure to ensure the tightness of the envelope structure and low air leakage rate.

(3) A constant air volume device is arranged on the air supply and exhaust ducts of each ward to ensure that the air supply and exhaust volume of the room are constant, thereby ensuring the constant pressure of the room.

Point 5: Ensure stable and reliable system operation

(1) The key to the use of a negative pressure ward is the maintenance of negative pressure. Uncontrolled negative pressure will cause severe cross infection. Therefore, a backup unit should be set for each exhaust fan unit, and the standby unit is automatically turned on after the unit fails to ensure that the negative pressure is maintained, and it can also be used as a backup during equipment maintenance.

(2) The equipment uses power with dual power settings to ensure reliable power.

Photo of negative pressure ward and ICU in Wuhan Vulcan Mountain Hospital

5. Basic requirements and key and difficult solutions for electrical design

(1) Basic requirements for professional design of strong electricity

1. Negative pressure ward and ICU should be equipped with dual power supplies

The dual power configuration meets the requirements of the negative pressure ward specification to ensure that there is a backup power source for the medical power supply of the negative pressure ward if there is a problem with the one power supply.

2. The negative pressure ward and the ICU should be equipped with an emergency power supply (UPS) to ensure the safe and reliable power supply of highly transmissive negative pressure wards and the ICU such as respiratory infectious diseases (such as SARS).

3. Each bed in the ICU ward should be provided with a separate power supply interface and separated from the electricity for auxiliary rooms. At the same time, a medical IT system should be configured to completely isolate the electrical between the primary side and the secondary side, and also isolate the circuit, isolate dangerous voltages, reduce the capacitance current to ground, which is small enough to cause harm to humans and ensure the safety of patients' electricity. .

4. In places such as clean corridors, dirty toilets, waiting rooms, consultation rooms, treatment rooms, and wards that require sterilization and disinfection, ultraviolet germicidal lamps are required for sterilization. Different switches should be used for germicidal lamps and other lighting fixtures. Easy to identify and operate.

5. Protective grounding and equipotential grounding: The components of the negative pressure ward and ICU electrical devices are in contact with the patient, and the patient is in danger of electric shock. "Auxiliary equipotential bonding" must be implemented, that is, all metal components and pipes in the site are interconnected with PE wires. The purpose of equipotential bonding is to make all metal components at the same potential as the PE wire to reduce the contact voltage and improve the level of safe electricity consumption.

(2) Basic requirements for weak current intelligence

1. Configure emergency broadcasting and public broadcasting system

The negative pressure ward and ICU are equipped with ceiling speakers in the corridor and ward, and the broadcasting host is placed at the nurse station. Receive a fire signal to play an evacuation broadcast during a fire, and can usually perform functions such as playing music and broadcasting to find people.

2. Monitoring system

Negative pressure ward and ICU ward entrance and exit are equipped with surveillance cameras, the host is set up and the nurse station is convenient for nurses to use. Use video surveillance to prevent cross-infection, and identify and record people who go in and out for later inquiry.

3.Access control system

The entrance of the negative pressure ward and ICU ward is equipped with an access control device. The door can be opened by swiping cards, passwords, fingerprint recognition, and face recognition lights to prevent unauthorized people from entering.

4. Integrated wiring system

Configure the telephone network and cable TV points. The telephone network points should meet the medical staff's requirements for communication and collection of patient information. The television points should meet the medical staff's and patient's education requirements.

5. Medical Intercom System

The medical intercom system of negative pressure ward and ICU ward, the call station is set at the nurse station, the call extension is set at the ward and the bed, and the two-way voice intercom function should be implemented; meanwhile, the call equipment in front of the bed should be easy to clean and disinfect.

6. Ward video surveillance and visiting system

Negative pressure ward and ICU ward are equipped with patient visiting system, nurse station is equipped with visiting main unit, visiting room is equipped with visiting extension unit, ward and bed are equipped with visiting extension unit; visiting system should adopt two-way voice and video communication; terminal on the patient side of visiting system Equipment should be easy to handle and disinfect.

3.Major and Difficulties in Electrical Design and SolutionsPriority

Focus 1: Security guarantee for power supply and distribution

This project uses dry-type transformers without filters. Therefore, the negative voltage ward and the ICU's total power distribution box are equipped with filters, which can dynamically compensate for reactive power and compensate for three-phase unbalanced current. Loss, improve the energy efficiency of power supply equipment, and provide a strong safety guarantee for the normal operation of medical electrical equipment.

Focus 2: Lighting support for emergency evacuation

The evacuation lighting and exit instructions for negative pressure wards and ICU wards should be powered by batteries, and the continuous power supply time should not be less than 30min. At the same time, the illuminance of emergency lighting in ICU Class 2 medical electrical places is not less than 50% of the illuminance under normal conditions.

Focus 3: Double door interlocking airflow safety guarantee in isolation area

Medical personnel enter the buffer room of the negative pressure ward using a double door interlocking device to prevent the pressure gradient caused by the simultaneous opening of the double doors of the buffer room in the negative pressure area, resulting in cross-flow of air and cross infection.

Focus 4: Design and Construction

1.It is necessary to provide the total power of the negative pressure ward and the ICU and the configuration and installation position requirements of the main power distribution box in the design stage before construction in order to reserve the power distribution box.

2.Docking with weak power units and providing reserved numbers of telephone network points so that weak power units reserve telephone and network switch ports.

3. Provide equipotential grounding reserve drawings, and reserve the equipotential grounding flat iron before ground leveling.

6. the basic requirements of water supply and drainage professional design and key difficult solutions

(I) Basic design requirements:

1. In order to meet the needs of rapid construction, the domestic water supply and drainage pipes of the negative pressure ward used plastic pipes in compliance with the provisions of the "Sanitary Standard for Drinking Water" GB5749.

2. All negative pressure isolation wards, negative pressure ICU wash basins, etc. are equipped with hot water, which is convenient for medical staff.

3. Negative pressure ICU endoscope cleaning is equipped with pure water system.

4. All taps are non-contact or non-manual switches.

(II) design difficulties and solutions:

Priority 1: Guaranteed water quality of negative pressure ward

1.The water supply system is equipped with a sterilizer to ensure that the water quality meets the GB5749 "Sanitary Standard for Drinking Water" standards.

2.The backwater preventer is equipped in the proper area to prevent pollution.

Point 2: how to deal with negative pressure ward and negative pressure ICU drainage

1. The high-efficiency filter should be installed on the drainage vent pipe of the negative-pressure ward, and the ventilation riser should be kept away from the air inlet and the area where people move, to ensure the safety of the outdoor environment.

2. Negative pressure ward drainage pipe is set separately and connected to the hospital disinfection tank and sewage treatment system for safe discharge.

3. In order to ensure that the indoor environment of the negative-pressure ward is not polluted, there is no cleaning port, maintenance port or floor drain in the department. It is necessary to set a water seal below the floor drain and a water seal 50-70mm.

7. the basic requirements for professional design of medical gases and key difficult solutions

(I) Basic design requirements

1. The negative pressure ward and the negative pressure ICU medical gas delivery pipe are made of copper. Copper has good anti-corrosion ability, especially strong antibacterial ability, easy construction and easy welding quality assurance.

2. All beds in negative pressure isolation ward are equipped with oxygen terminal and negative pressure terminal; compressed air terminal is recommended for backup.

(II) Design key difficulties and solutions:Key point one: medical gas safety guarantee

1. Negative pressure suction station room is not suitable for common ward, it is set up independently, and the station room is equipped with a filter to sterilize.

2. Check valve is installed on the medical gas pipeline of the negative pressure ward to prevent pollution.

8. Design considerations on how to achieve quick installation and fast delivery

1. Professional decoration: The cleanroom is designed to a uniform standard size, and the cleanroom wall panels and the top surface are made into a fixed size module. The cleanroom doors and windows are designed according to standardized sizes to achieve modular production and rapid installation.

2. HVAC specialty: new and exhaust unit selection and automatic control system solutions communicate technical solutions with equipment suppliers during design, please manufacturers to provide simultaneous production of supporting products to achieve the fastest supply; the air duct system uses as many as possible A standard air duct model realizes mechanized processing and rapid on-site installation; the exhaust branch pipe is connected by finished PVC round pipes, saving labor.

3.Electrical specialty: All the top wires go through the bridge, and the wall wires go through the PVC pipe to achieve a fast installation method.

9.Concluding remarks

The negative pressure ward and ICU ward of Wuhan Vulcan Mountain Hospital have worked through the technical team for 60 consecutive hours and completed the work from scheme design to construction drawing design. Through the 150-hour continuous operation of the procurement, engineering construction and commissioning team, material procurement, All the work of construction and system commissioning, and passed the detection of indoor environmental indicators by Hubei Provincial Center for Disease Control and Control, smoothly transferred to the military for use. The delivery of this project will make an important contribution to the fight against the epidemic in Wuhan and save the lives of patients with severe new coronary pneumonia.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.