We have a passion for unconventional solutions that bring your vision to life.

Cleanroom Panel Construction Steps:

1. Before installation, the dust, dirt and alkali film on the surface of the base layer should be carefully cleaned up.

2. The process flow of clearoom partition wall panels decoration installation is carried out according to the principle of "down first, then up" in order to reduce repairs and protect the finished product.

3. Seal the same color sealant at the joints of the cleanroom wall.

4. Clean the surface after installing the cleanroom panel.

Cleanroom Panel Quality Requirements:

1. The cleanroom wall panel should be installed vertically and the top panel should be installed horizontally.

2. The installation gap should be even and the sealant filling should be sufficient.

3. The cleanroom panels must not have scratches.

Cleanroom Panels Construction Requirements:

1.1. Familiar with the cleanroom drawings, carefully review the plan layout of the cleanroom panel, node requirements, the connection between the cleanroom panel and the building, the color, filling, basic size requirements of the clean board itself, the size and layout of the cleanroom doors, cleanroom window, and the type of auxiliary materials and other unknown content.

2. Secondary board drawing, this is an important step in the prefabrication and installation of cleanroom panels. It is to transform the design drawings into a second processing in the factory. The standard specification boards are made into different types of wall panels and combined to reflect the design intent. In the color steel plate factory, standard plates are produced and assembled at the construction site to ensure the firmness of the wall panels and speed up the installation speed of the color steel plates.

3. When prefabricating in a clean room factory, cleanroom door openings, cleanroom windows openings and seams fully consider the clearance and installation margin. And during the entire transportation, production, and installation process, prevent scratches, heavy pressure and surface impact to prevent uncorrectable pits and scratches. The plastic protective films on both sides of the cleanroom panels are only allowed to be torn off after the installation is complete and thorough cleaning is performed.

4. The unwinding work before the installation of the cleanroom panel of the clean room should be carried out after the completion of the ground, and can only be carried out after the other relevant installation conditions such as the larger equipment has been transported in place, the pipeline has been adjusted and the main installation work of the technical interlayer has been basically completed . Pay-off is to mark the horizontal projection of the cleanroom panel (50mm wide) and the position of the doors and windows on the ground.

5. For wall panel installation, install the prefabricated components according to the layout drawing, and connect the adjacent wall panels with aluminum with Chinese characters. It is worth paying special attention to the installation of the clean room wall panels and the matching of the electrical pipelines and boxes. The wallboard should be vertical, and the vertical seams should be tight. The smaller the gap, the more beautiful it is, and the vertical seams are even. During operation, carefully clean the protective film on the vertical seam and temporarily uncover it, but never remove it. Clean up the sundries in the tank and the glue solidified hard blocks. Otherwise, it will be difficult to adjust the vertical seam uniformly and densely with no amount of force.

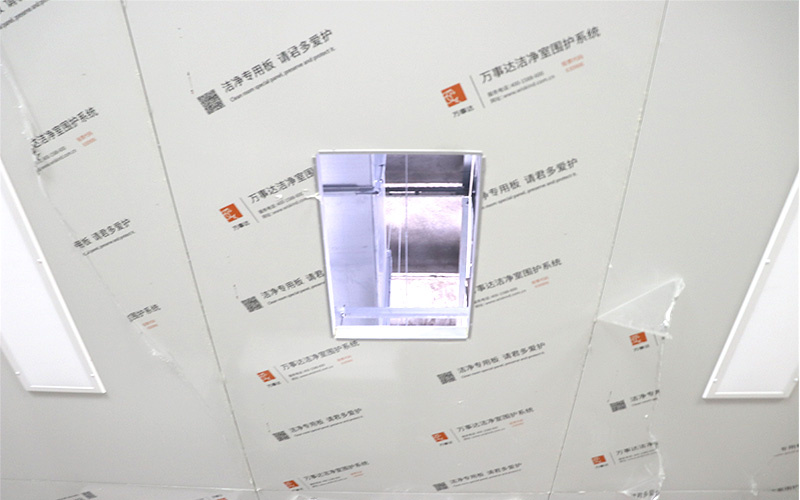

6. The cleanroom ceiling panel is installed, and the weight of the cleanroom ceiling systems is supported by the vertical plate fixed on the periphery and the z-shaped aluminum suspended in the middle. The cleanroom ceiling panel needs to be flat, and the board seams are dense and uniform, smooth, without marks and no injuries.

7. Sealing silica gel. In the clean area, all the following gaps that may affect the cleanliness should be coated with sealing silica: the splicing seams between the clean plates, all the gaps between the R corners and the wall panels and the ceiling; , The gap between the high-efficiency filter and the wall top plate; the gap between the protective pipe groove and the edge of the opening of the electrical passage through the wall plate top plate; the gap between all switch socket lamps and the color steel plate top plate surface; all processes, water supply and drainage, protection pipes and The gap between the hole; the gap between the glass and the frame; the sealing silica gel should be installed on the clean plate basically, and the sanitary conditions are good. After thorough cleaning and dust removal, the clean room is unified. Otherwise, the silicone seam is easy to be polluted and blackened. Within 24 hours after the silica gel is finished, there should not be a lot of dust and water washing the ground, which may affect the curing and fastness of the sealing silica gel.

Wiskind Cleanroom specializes in cleanroom enclosure system , ceiling system, cleanroom doors and windows and related product development, manufacturing, sales, consulting and services.